Duravit China continues to invest with SACMI

The Chongqing plant is increasingly establishing itself as one of the world’s most advanced facilities in terms of automation and Industry 4.0 production flows and internal logistics.

Duravit China is pressing ahead with its investment plan aimed at doubling the production capacity at its Chongqing facility. Launched in 2023 with an upgrade of the body preparation department to boost production to 2 million pieces annually, the plan has now reached another key milestone with the doubling of internal logistics capacity alongside further development of the casting department.

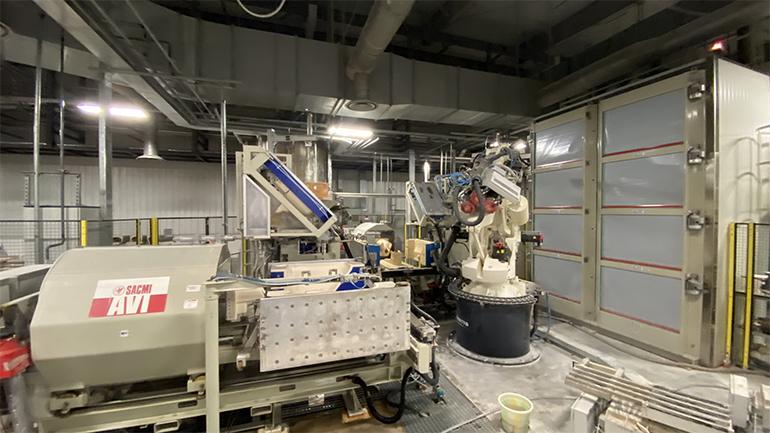

Two additional AVI casting cells were recently put into operation, increasing the total number of these machines installed at the Chongqing plant to 10 since 2021. In keeping with previous investments, this latest project fits in with the AVI philosophy of a casting cell at the service of a robot, allowing for the production of highly complex pieces with maximum versatility and rapid mould changeover. As on all machines of this kind, the robot handles most operations automatically, from mould assembly and rim attachment to demoulding and depositing in the pre-dryer.

This investment further testifies to Sacmi’s role as a valued partner in product development, thanks to its porous resin moulds that undergo advanced functionality tests to ensure the best possible results during production.

The latest factory logistics project completed at the Chongqing plant is a new system for controlling and managing the routing of the 24 Sacmi LGVs, which are responsible for transporting pieces from the casting to the glazing departments. This system is now integrated with the new section of the plant, creating two interconnected, interchangeable networks that optimise the management of all processes through real-time data exchange.

This solution demonstrates the effectiveness of the Sacmi LaserMove solution in conjunction with the HERE Sacmi supervision software, completing the automation of the entire sanitaryware production process. The plant is now one of the most advanced facilities of its kind in the world in terms of Industry 4.0 production flow management.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks