Organized by the B&T Group, in the Castellón ceramic cluster, the Open House along with a tour of all the main ceramic client facilities.

Following the excellent results achieved at Tecna, Gruppo B&T is preparing to present its latest technologies to the Spanish market. The Italian group’s upcoming promotional activities in the Castellón ceramic cluster will culminate in an open house event held during Cevisama in late February along with a tour of all the main ceramic client facilities, where visitors will have a chance to observe the technologies installed.

The initiative is promoted by B&T Iberica, the Italian group’s longstanding subsidiary which for the past 40 years has been supplying high-quality complete plants backed up a rapid and efficient after-sales service.

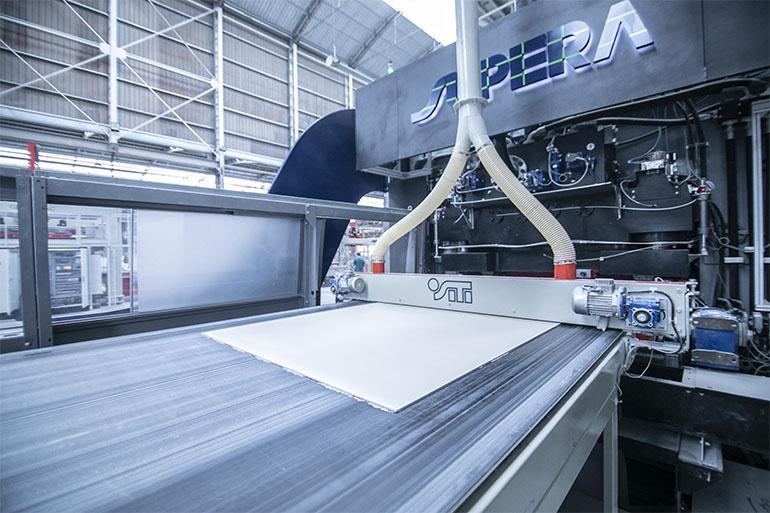

During the event, visitors will have the opportunity to observe the operation of Supera®, the compact and versatile mouldless pressing technology designed for the production of large slabs with unique aesthetic qualities. It is now available in a new Rapida version suitable for the production of more traditional sizes and with a very high level of productivity (24,000 m²/day). It also features new smart systems capable of guaranteeing high flexibility and versatility with low energy consumption.

The group will also be showcasing its Titanium® 2.0 kilns with best-in-class performance in terms of energy savings (more than 30% lower consumption) and emissions reduction, complete with a system that maintains a uniform temperature at every point in the module.

In addition, visitors will have a chance to admire the latest digital decoration solutions from Projecta, including the new PRO printer with exceptional computing power, the new generation of Fast Drop printheads, and the Dry Fix grit applicator which can be used to create sophisticated textural effects and has already reached more than 150 installations.

Other solutions on display will include Tornado, the new high-speed dry squaring machine from Ancora complete with advanced automation and self-adjustment systems using laser beams, and the new Magister packaging machine for sizes up to 120x120 cm combined with a stacker and palletiser.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks