Three-dimensional surfaces: BVERSO, More Is Less

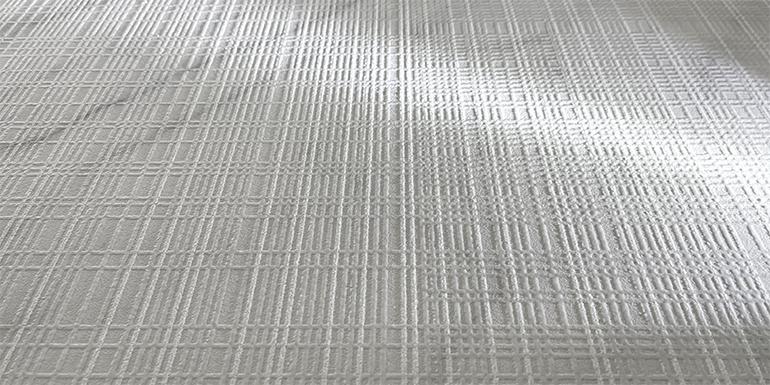

Vetriceramici presents BVERSO, a breakthrough in material application, a simple, innovative method that uses a single grit to generate a variety of 3D finishes and textures for creating truly unique products.

By Eros Giavelli (Vetriceramici-Altadia Italia)

Today, three-dimensional ceramic surfaces are typically created using additive techniques, applying either solvent- or water-based adhesives followed by grit. The grit is fixed in place either with digital adhesives, which are capable of bonding one or more types of grit, or by new-generation machines that apply water-based digital glazes prior to the engobe.

Now, however, an alternative approach is available: BVERSO.

BVERSO is a breakthrough in material application that Vetriceramici aims to position as a new industry standard, offering the ceramic sector a solution for creating products that are both truly unique and increasingly aesthetically appealing.

The origins of BVERSO

In 2021, Vetriceramici introduced a new application method called “3D Before Technology” to a select group of clients. The technique involved applying grit between two layers of engobe and achieved exceptional definition, precise material distribution and a strikingly three-dimensional finish. Vetriceramici was the first to believe in this innovative technology and promote it in the ceramic sector, at a time when no one had yet considered using adhesives and grit prior to engobing and digital decoration. The same spirit of innovation also prompted the company to pioneer the use of water-repellent or resist agents before the engobe application and drying phases, another practice that has now been adopted in a number of facilities.

Three-dimensionality as a sensory experience

There is growing demand in today’s market for textured, three-dimensional surfaces. Architects in particular appreciate materials with pronounced textures, raw surfaces and deliberate imperfections, features that become an integral part of a product’s visual and tactile identity.

This trend, which is perhaps sociological as well as aesthetic in nature, extends beyond ceramics to materials such as wood, polycarbonate and plywood as part of a decisive shift towards surface texturisation.

At the same time, environmental sustainability is a growing priority, driving demand for low-impact, locally sourced materials that help reduce carbon emissions.

BVERSO technology

BVERSO is a patent-pending technology capable of creating three-dimensional ceramic surfaces. It is a simple, innovative method that uses a single grit to generate a variety of finishes and textures and can be integrated into any production line. Initial industrial trials with customers have already delivered promising results.

So what are its advantages?

First, the process is straightforward and easy to adopt on any production line: it involves applying digital products and special abrasives using widely available machines and familiar technologies.

Second, it offers a high level of customisation in ceramic tile design, enabling manufacturers to create unique, natural-looking products that can easily be engineered to meet their specific needs while being recognisable in the marketplace and difficult to imitate.

Third, the process allows a wide variety of 3D effects to be obtained on a single ceramic surface. Using a single high-thickness, textured grit, manufacturers can differentiate tiles within a collection or even achieve three or more different finishes (matt, glossy, transparent, opaque or coloured) on a single tile.

The materials: B-Grits and B-Fix

BVERSO technology is based on two key materials:

- B-Grits: specialty grits with specific chemical and physical properties and particle size;

- B-Fix: textured fixer inks available in solvent-based (Fixer Solvy) and water-based (Fixer Hydro) versions, the latter compatible with high-discharge printheads already available on the market.

A single B-Grit can yield a wide range of surface effects in combination with any of the four types of B-Fix inks: Snow for white textures, Matt Velvet for material textures such as stone, Satin Stone for soft, waxy textures, and Shine for glossy, transparent textures. These inks can be blended to create intermediate textures or used in combination on a single tile.

Looking ahead

The excellent results achieved to date show that BVERSO can play an important role in the future of ceramic surfaces. In addition to the advantages described above, particularly the ability to create unique, highly distinctive materials, it delivers clear environmental and operational benefits. By using a single grit and varying only the fixers (which alter the chemical and physical properties of B-Grits), it reduces material waste, pollutant emissions, grit applicator cleaning time and flue emissions (by reducing the amount of material requiring firing) and optimises warehouse management.

In short, it is a forward-looking solution for the production of high-value ceramics.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks