GSI Ceramics again opts for Sacmi pressure casting

In recent months the company has started up its fifth Sacmi ADM casting machine and two new Sacmi AVM cells, all of which are fully automated, state-of-the-art solutions.

GSI Ceramica, a leading player in the Italian ceramic sanitaryware industry, has recently completed new investments in casting technology from Sacmi, its trusted technology supplier for over 40 years.

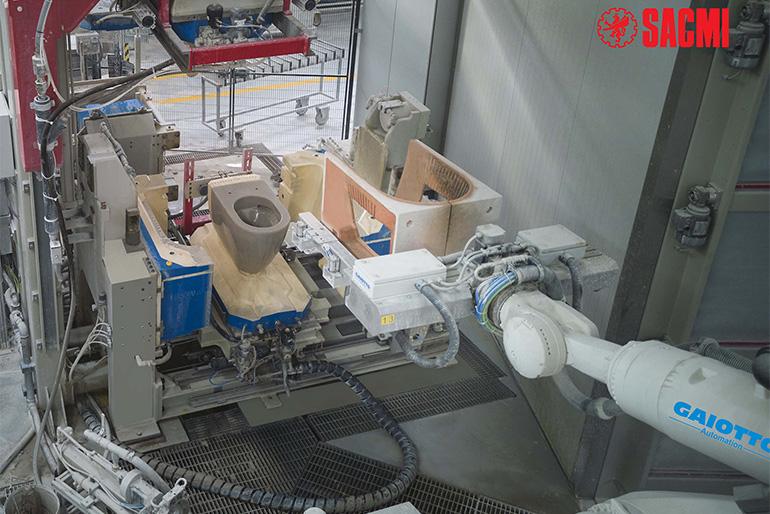

The company has installed two additional AVM cells for the production of complex WCs at its site in Gallese (Viterbo), bringing the total number of such cells in operation to 11. They are all equipped with latest-generation automation systems, such as transfer to the Sacmi FPV pre-dryer, green piece finishing and automatic loading onto the transfer car. The AVM cell is the most popular single-mould casting machine and Sacmi’s most widely-sold model with a total of 280 installations completed worldwide by the end of 2023.

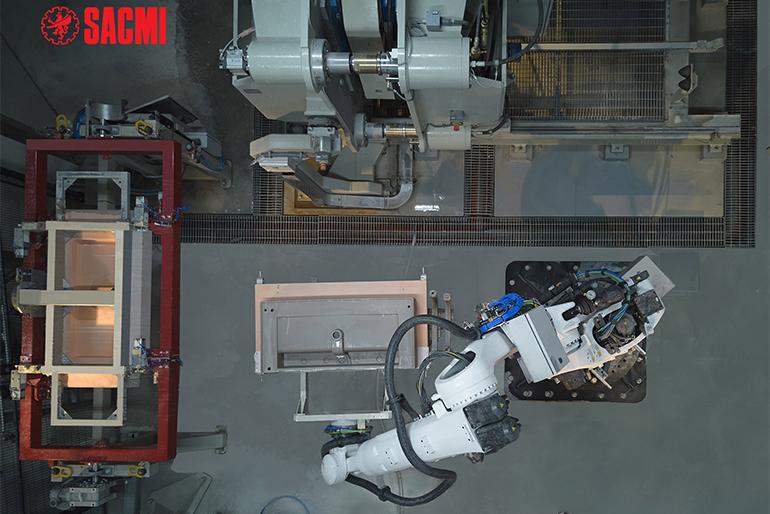

This latest investment follows on from the one completed by GSI in the second half of 2023 when it started up its fifth Sacmi ADM pressure casting machine for the production of washbasins and consoles. As part of the Sacmi RobotCasting machine range, the ADM single-mould casting module stands out for its versatility in the production of pieces using two-part moulds. Here too, all handling operations are performed without any manual intervention, from casting through to loading the piece onto the car for subsequent processing.

The progressive automation of all production stages has enabled GSI to improve both product quality and efficiency as part of its efforts to achieve optimised and consistent management of the entire production flow.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks