NG Kütahya Seramik to adopt Carfer AR10 valves on its kilns

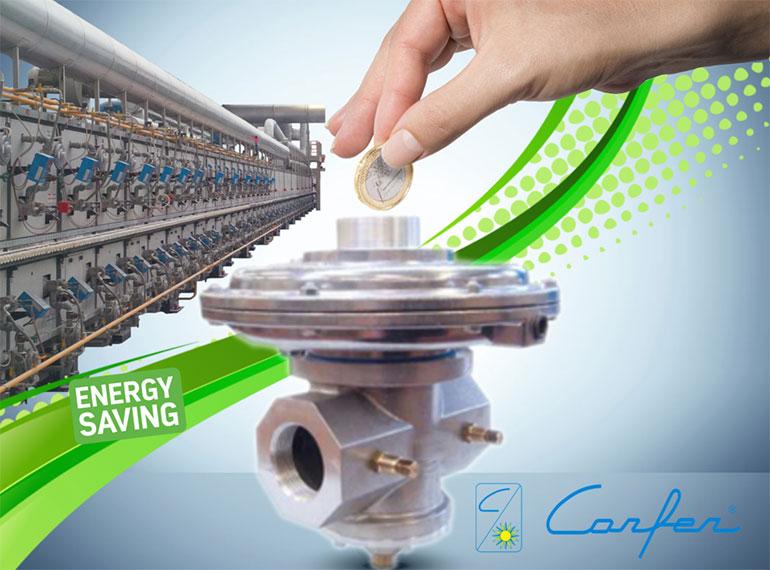

The Turkish tile manufacturer will install high-efficiency valves from Carfer to reduce the fuel gas consumption of its kilns by up to 15%.

Carfer AR10 valves have been used for a number of years on roller kilns operated by top Turkish tile manufacturers and will soon also be supplied to NG Kütahya Seramik.

The aim is to lower the energy consumption of the kilns in order to reduce the impact of rising natural gas prices. Carfer AR10 valves reduce fuel gas consumption by up to 15% and consequently cut down on emissions compared to conventional fixed combustion air systems. This is due to the automatic proportional control and regulation of combustion stoichiometry (air/gas combustion ratio) on each individual burner in the kiln.

Thanks to the experience of Carfer’s engineers combined with the high level of reliability and flexibility of the control system, the valves can be installed and set up rapidly on any kind of burner mounted on single or double channel roller kilns used to fire any kind of tiles.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks