System Ceramics unveils its latests innovations

System Ceramics to showcase its forming, decoration and end of line technologies at Tecna 2024 and at its Open House in Fiorano Modenese.

Innovation is a defining trait of System Ceramics, a Coesia Group member company which is committed to systematically exploring all potential advances in ceramic technology with the aim of providing tile and slab manufacturers with the best process solutions.

This commitment to innovation will be showcased at three events this September:

- Tecna in Rimini (Hall B5, Booth 300-301);

- Cersaie in Bologna (Hall 33, Booth E34) where the company is exhibiting together with the Tosilab brand;

- the “Inside Innovation Valley” open house event to be held at the company’s headquarters in Fiorano Modenese from 18 September to 2 October.

At these events, System Ceramics will present solutions that improve efficiency, precision and aesthetic quality in the pressing, decoration and end-of-line stages.

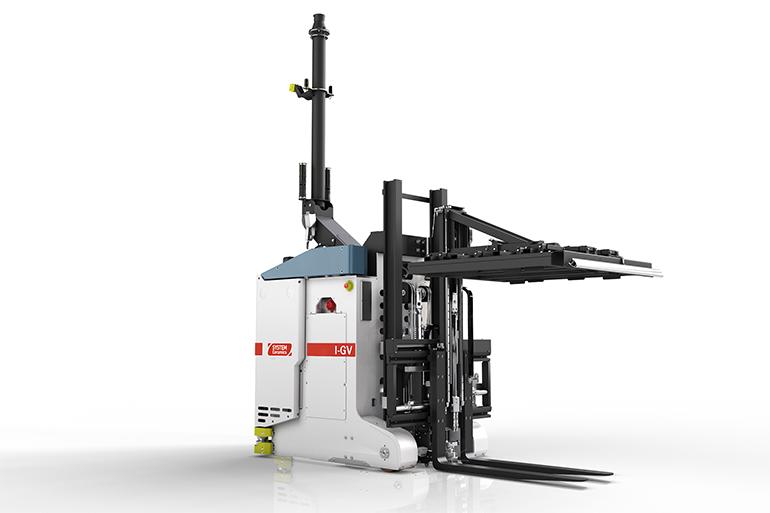

One standout innovation for the end-of-line stage is the new I-GV (Intelligent Guided Vehicle), an autonomous laser-guided vehicle developed entirely in-house and designed to handle loads of any size.

Another notable handling solution is Rotostore, a 4+1 automatic robot designed to efficiently load and unload fired material from the production line to loading platforms and vice versa. This high-performance patented machine uses a robotic arm equipped with a double row of suction cups to lift either two rows of tiles simultaneously or a single, heavier row.

Digital printing goes to the next level

In the field of digital decoration, this year System Ceramics is presenting two major new versions of Creadigit Infinity, a solution renowned internationally for its unparalleled quality and computing power.

The first is Infinity SKY, a solution that takes print quality to the next level and sets new standards in terms of detail and resolution, which are crucial to the quality of the finished tile. A milestone in the history of digital printing, it is an advanced technology platform that is intended to meet the needs of the market for the next 10 years. It is extremely reliable and features a wear-reducing system designed to keep it in optimal condition. Available in two machine configurations, one with 4 and the other with 8 colours, it supports 12- and 16-bar modularity. Both versions are equipped with a pneumatic lifting mechanism complete with a protection system that can be activated when the machine is not in operation.

But what really sets Infinity SKY apart is the new self-maintenance process designed to keep the printheads in optimal condition, thereby guaranteeing a longer machine life, extended print activity and high quality performance over its entire lifetime.

During the lifting phase, an inverted hydraulic recirculation system activates to replace and empty the ink in the tank and to recover the solvent extracted from the deaerator. The inversion circuit is optimised by means of plastic plate closure and activation of ultrasound in both stand-by and production mode, causing any sediment present inside the printheads to disintegrate.

This process is also aided by the use of water-based inks, a solution that System Ceramics pioneered in 2016.

Finally, in the printing process the transport phase consists of a maximum of three belts: infeed, outfeed and a central belt. This latter belt is always present to ensure efficient and continuous transport during the printing process.

The second new version of Creadigit Infinity is Infinity DRY, a new digital grit and powder deposition system that is capable of applying grits and powders to selected points on the tile surface to create multiple versions of digital designs. System Ceramics has once again demonstrated its pioneering vision and further raised the bar for digital decoration by combining digital decorative and grit bars in a single module. This means that dry material can be applied in a single pass, ensuring maximum precision and minimising wastage of material and the presence of impurities in the recirculation process.

A major upgrade in the field of digital decoration concerns Digiglaze, the well-known digital glazing machine for energy-efficient glazing of ceramic substrates, which is capable of handling large slab sizes up to 1800 cm.

Last but not least, Genesis is back in the spotlight after the presentation of the prototype at Tecna in 2022. Two years later, it is firmly established as a proven and successful solution for full-body three-dimensional decoration, with digital control of the coloured spray-dried powder discharge at the various chosen points on the slab according to the set graphic design.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks