Indian clays for ceramic slab production

Among the various types of clay produced by JLD Minerals, those containing the mineral illite have emerged as particularly beneficial in the production of large format porcelain tiles.

Large ceramic slabs, known for their size and versatility, are rejuvenating the ceramic sector by offering a technical and aesthetic alternative to natural materials such as natural stone. Their aesthetic appeal and rugged nature have paved the way for diverse applications, ranging from countertops and flooring to wall cladding, marking a significant shift towards more versatile and visually striking environments.

The production of large ceramic slabs, however, introduces a complex set of challenges.

Given their large size, ensuring that these slabs are defect-free, durable and robust requires meticulous attention to detail and a profound understanding of the materials involved. The complexity and technicality of manufacturing large ceramic slabs underscore the critical role of clay in the success of these projects. Selecting the right type of clay is not just important, it’s fundamental to achieving the desired outcome, influencing everything from the slab’s aesthetic qualities to its structural integrity.

Among the various types of clay, those containing the mineral illite have emerged as particularly beneficial in the production of large format porcelain tiles.

Illite, a member of the mica family, is known for its non-expanding clay mineral properties, which bring several benefits crucial for large format tile production. Its inclusion in the clay mixture enhances the elasticity of the tiles, an essential feature for large slabs that must withstand various stresses. Illite also plays a significant role in mitigating shrinkage during the firing cycle, thus reducing the risk of deformities. Additionally, it contributes to increasing both green and fired strength, ensuring that the tiles are durable and robust from production through to installation. Moreover, illite improves the workability and homogeneity of tile mixtures, facilitating a smoother manufacturing process and higher quality end products.

The aspects to be considered when choosing the most suitable type of clay extend beyond its mineral composition.

For large ceramic slabs, the ideal clay must exhibit exceptional fusibility and near-zero water absorption to ensure longevity and aesthetic appeal. Stability is another crucial factor, as it guarantees the consistent quality of production. Moreover, the clay should contain minimal carbon and sulphur to prevent firing defects such as black core and to minimise kiln maintenance, respectively. The requirement for white firing clay further emphasises the need for versatility in application, allowing for optimal decoration and finishing that can accommodate a wide range of design preferences.

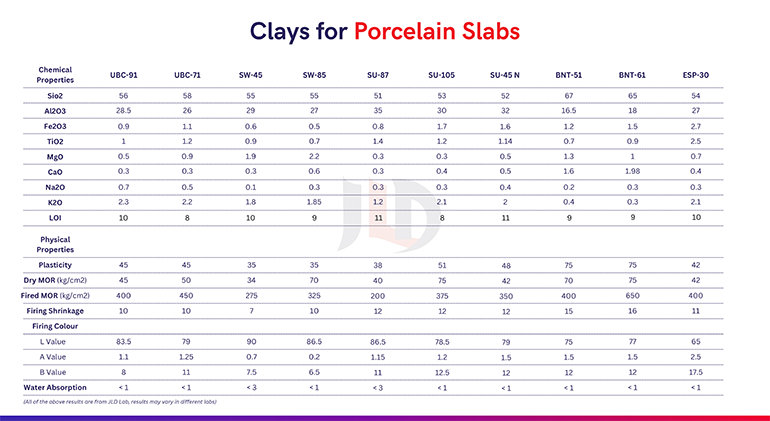

Recognising the unique challenges posed by the production of large ceramic slabs, JLD has positioned itself as a leader in providing customised clay solutions tailored to the specific needs of manufacturers. Understanding that each production process is distinct, with its own set of challenges, JLD offers tailor-made solutions designed to address these issues head-on. With a portfolio of clays optimised for the manufacturing of large size slabs, JLD is supporting leading players in the global ceramic industry, enabling them to overcome the complexities of production and achieve excellence in their projects. An example of one such clay is UBC-71, which has an illite content of 22% and is renowned as one of the best in the world for porcelain slab production.

Founded in 1973 in Bikaner (Rajasthan), in the heart of India’s ceramic industry, JLD Minerals (Jaichand Lal Daga Group) is a family-owned company with a strong focus on innovation and the pursuit of excellence. Over a period of 50 years, it has grown into a mining industry giant. It operates more than 30 mining sites, possesses state-of-the-art facilities for the production of feldspar, quartz, silica sand and granite, and has a portfolio of more than 50 varieties of clays for a wide range of applications, including tiles, sanitaryware, tableware, refractories and bricks.

Its team of highly skilled technicians and a world-class laboratory spearhead the development of the company’s engineered clays portfolio. In 2023, the company inaugurated a state-of-the-art clay blending and processing plant. This facility is not only the largest in India but is also one of the biggest in the world, testifying to the group’s relentless pursuit of technological progress.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks