World of Finishes opens the door to digital finishing

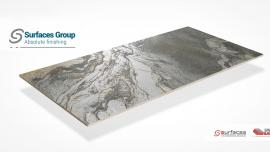

Surfaces Group’s WOF project allows for unprecedented shade variations and effects that make each slab utterly unique and original but at the same time easily replicable.

Surfaces Group has emerged as a prominent player in the ceramic surface finishing and treatment sector, driven by its innovative capacity and the technological solutions developed through the collective expertise of its brands (Adi, Surfaces T.A., Luna Abrasivi, Nocoat, International Chips, Vincent and RBM Italia).

Today, Surfaces Group offers synergistic solutions that unlock vast potential in surface finishing. One of these is the World of Finishes project, which opens the door to digital finishing.

World of Finishes allows for an unlimited range of finishes, a multitude of different textures and previously unimagined colours on natural ceramic surfaces, solutions that prove particularly effective on large format tiles. With World of Finishes, creativity is limited only by the designer’s imagination.

But the truly revolutionary aspect of World of Finishes for ceramic floor and wall tile surfaces is the way that tools originally designed for other application processes are used to create unprecedented shade variations and effects that make each slab utterly unique and original but at the same time easily replicable.

The process begins with surface smoothing using Surfaces T.A. preparatory fickert tools, followed by satin finishing with Luna Abrasivi’s Flexy Velvet line tools. These tools have varying geometries and adapt to different plants so as to meet all ceramic surface requirements. The final stage in the process involves the use of Surfaces T.A. tools, normally adopted for full-field lapping.

All these tools, combined with a dynamic but controlled machining process powered by latest-generation software, create WOF.

The various combinations allow for a wide range of variations, ensuing unique results for each tile. The tailor-made system is suitable for both fully polished and non-flat, crest-machined surfaces.

The Surfaces Pilot Plant in Sassuolo, Italy is at customers’ disposal for studying the most suitable recipe for each machining operation (tools, software, dedicated machine setup) and for testing the process before starting production.

World of Finishes goes beyond merely supplying tools and acts as a highly qualified partner, providing customised solutions that ensure the success of every project.

Find out more at:

→ Surfaces Group

→ World Of Finishes

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks