Bongioanni launches a new-concept hydraulic presses

The new IP92 press has been developed in in close collaboration with Bosch Rexroth and SEW.

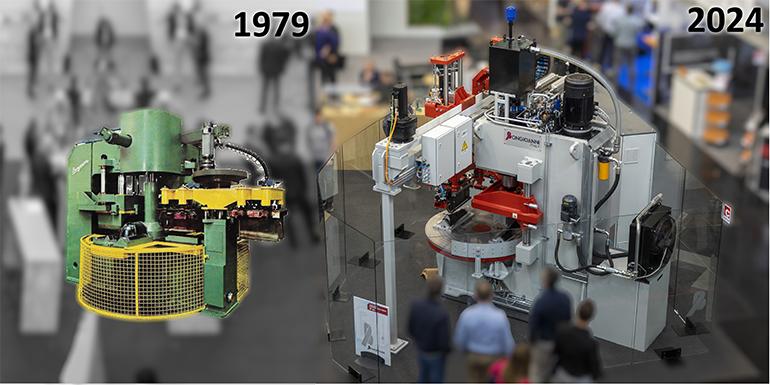

Forty-five years have gone by since Bongioanni Macchine unveiled its first hydraulic press – the IP4S – at the exhibition Ceramitec in Munich, transforming the brick and tile industry in the process. Since that momentous launch back in 1979, the company has continued to pursue technological progress in the field of hydraulic presses, leveraging its experience and forming strategic partnerships with leading manufacturers in the sector. This ongoing commitment to innovation culminated in the launch of the ninth-generation IP92 press in May 2024, once again at Ceramitec.

Collaborations with Bosch Rexroth and SEW

Developed in close collaboration with Bosch Rexroth and SEW, the new model has a pressing force of 900 kN and a production capacity of 600 pieces/minute. The machine is designed to ensure not only high efficiency, but also reduced energy consumption. The incorporation of a 22 kW Rexroth variable displacement hydraulic pump significantly reduces the quantity of oil required for operation, thereby improving sustainability standards and reducing operating costs. The use of finite element method (FEM) calculations has further improved the machine’s robustness and longevity.

The design incorporates SEW brushless motors for both the 1500 mm diameter table movement and the loading and unloading system, ensuring precise and reliable piece positioning. The press is also equipped with a fall prevention safety system for the loader, deburrer and compressor, thereby improving safety during operation.

The configuration of the new press allows for a high degree of operational flexibility, with the possibility of setting single or double stroke pressing and a mould pack height of 350 mm. The hydraulic stroke can be varied up to 400 mm depending on the type of mould used, whether rubber, plaster or metal. This ensures excellent adaptability to different types of production, while maintaining the quality and integrity of the finished pieces.

More than just a press

The IP92 Hydromatic press is a modern, compact and fully integrated automated system that is ideal for installation in robotic production lines. This makes it a highly flexible solution that sets new standards in the hydraulic press sector and is ideal for companies looking to maximise efficiency and minimise downtime.

Investing in innovation

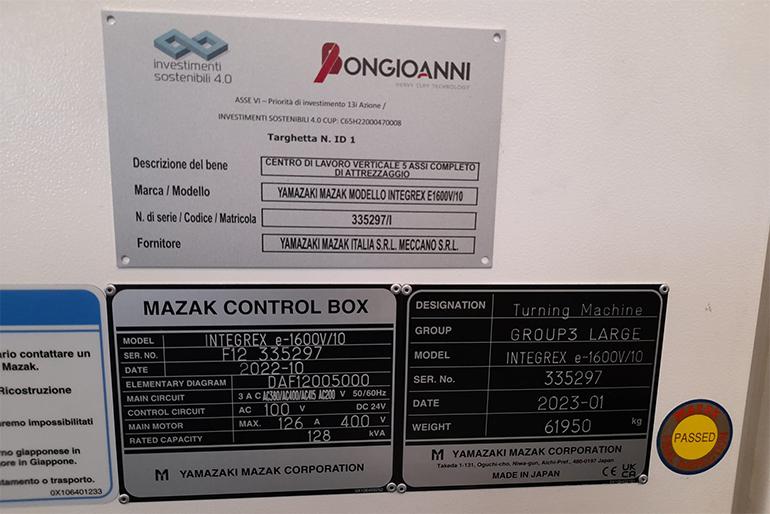

To drive technological innovation and increase operational efficiency, it is crucial to adopt the most advanced equipment. In line with this strategy, Bongioanni Macchine has installed a new Mazak Integrex E1600V/10 5-axis vertical machining centre at its Fossano plant as part of the ongoing Industry 4.0 investment plan initiated in 2022.

Renowned for its precision and reliability, the Mazak machining centre was chosen for its innovative features including advanced connectivity, real-time data analysis and the ability to communicate with other machines and systems within the factory. This enables Bongioanni to constantly monitor performance, rapidly identify problems and optimise production. Industry 4.0 compatibility brings numerous operational benefits. The ability to collect and analyse data in real time allows for predictive maintenance, reducing downtime and improving tool lifetime. In addition, advanced automation and integration with company management systems allow for greater flexibility and production customisation, resulting in a rapid response to customer needs and market trends.

With this new installation, Bongioanni is able to offer higher quality products with shorter delivery times, reaffirming its commitment to remain at the leading edge of the industry.

The investment was made using funds supplied by Invitalia under the Sustainable Investments 4.0 programme promoted by the Italian Ministry of Economic Development.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks