Ceramica Alice chooses Sacmi RobotClean

The well-known Italian sanitaryware manufacturer has installed a finishing cell with automatic handling.

Ceramica Alice, a leading Italian ceramic sanitaryware manufacturer based in the Civita Castellana cluster in the province of Viterbo, has recently installed the Sacmi RobotClean finishing system. This technology, which has rapidly gained popularity among ceramic companies in the Lazio region, eliminates manual handling operations while ensuring consistently high finishing quality.

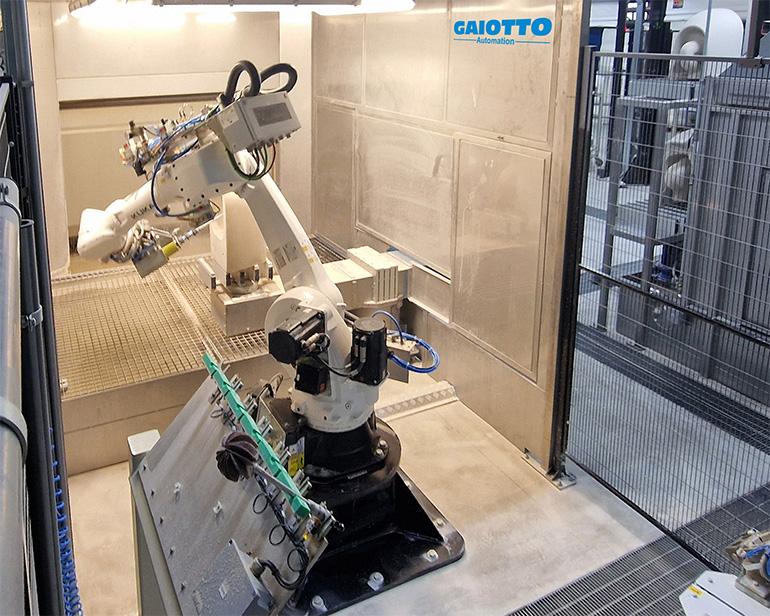

The fully automated finishing cell adopted by Ceramica Alice is equipped with two finishing robots and an automatic handling system that transfers each piece to the cell and then to the inspection station prior to glazing.

Once inside the cell, the robots carry out the finishing process using specialised abrasive tools, following precise recipes defined by Smart Offline NG software, Sacmi’s multi-platform, cross-application solution for automation control on the sanitaryware production line.

This complete white finishing ecosystem is the first of its kind on the market and marks a further step towards Sacmi’s goal of full production automation, with the twofold advantage of improving the working environment and achieving uniform finishing quality.

The supplied cell is programmed to interface with the customer’s factory supervisor, allowing for precise tracking of all operations performed on each piece, real-time data logging, real-time generation of quality statistics and monitoring of performance indicators.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks