Ceramica Dolomite adopts Sacmi’s AVM casting technology

Two new high pressure casting cells for WC production were started up at the Trichiana facility in December.

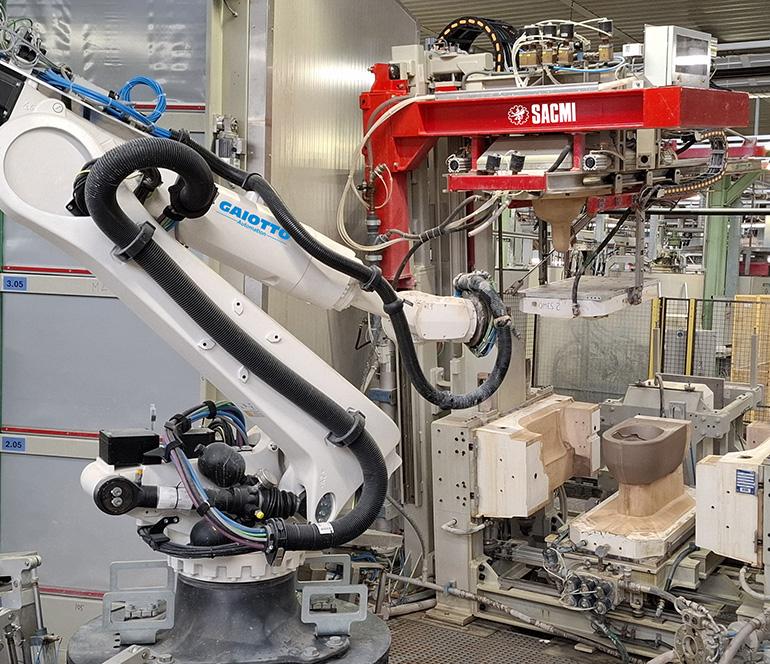

Ceramica Dolomite is continuing to invest in Sacmi’s advanced automation for sanitaryware production. At its facility in Trichiana (Belluno), the company has started up two fully configured AVM high-pressure casting cells equipped with robotized green finishing tools for WCs.

These latest additions complement the existing technologies implemented during the company’s 20-year partnership with Sacmi, including a Riedhammer kiln that has been in operation since 2018 and Gaiotto glazing cells in use since the early 2000s.

As well as supplying the new machinery, Sacmi has supported Ceramica Dolomite with the industrial rollout of its latest production models.

A steadfast commitment to design development and product excellence is at the core of this investment by the new owners, a group of Veneto-based entrepreneurs who acquired the brand in 2022. By prioritising quality and automation, they are preparing Ceramica Dolomite for the future, reinforcing its role as a benchmark in Italian ceramic sanitaryware manufacturing.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks