Minerali Industriali Engineering ready to showcase RECSolution at Tecna

The company will present its new range of scrap recovery technologies, an innovative solution in the field of pre-grinding.

At Tecna 2024, Minerali Industriali Engineering will be hosted in Hall D3, booth 302 within the exhibition space of Italtech, the new collaboration project launched by MIE together with Cimes, Inter Ser and I-Tech.

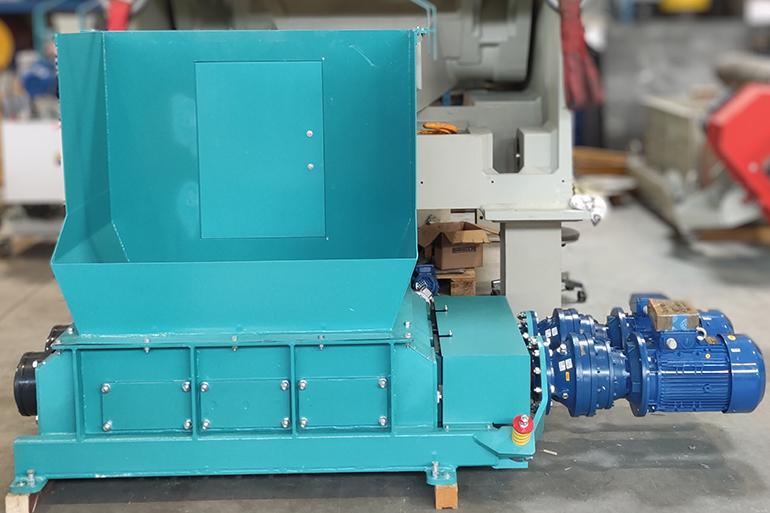

Specifically, Minerali Industriali Engineering will be exhibiting RECSolution, its new range of scrap recovery technologies that integrates seamlessly with the RECTiles and RECPitcher pre-grinding solutions thanks to the inclusion of a state-of-the-art crusher/calibrator.

The crusher/calibrator is an essential component for fired waste recovery plants and is specially designed to process material originating from large slab or sanitaryware production. It is capable of handling entire pieces with dimensions up to 1500x4000 mm and can adapt to different production requirements. One of its key features is its ability to reduce material to a piece size of less than 50 mm, with a throughput of 40 tonnes per hour, making the machine extremely efficient and suitable for handling large volumes of scrap.

Feed flexibility is another of the crusher/calibrator’s key strengths as it can be fed by means of a metal box feeder or directly from a dedicated hopper after making the necessary modifications to the gearmotor and transmission. This adaptability allows the process to be optimised according to specific operational requirements.

The machine is controlled by a PLC and an operator panel, from where the working parameters (speed, energy absorption, etc.) can be controlled precisely and intuitively. This advanced control system ensures efficient and safe operation, improving the quality of the final product and reducing operating costs.

The new technology from Minerali Industriali Engineering not only reduces industrial waste and promotes a more efficient use of resources but also addresses the shortcomings of traditional pre-grinding methods that obliged manufacturers to adopt unorthodox and hazardous techniques such as the use of mechanical shovels. At the same time, it reduces operating costs and increases pre-grinding speed.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks