Rethink, Recycle, Resource. Making a difference in the world of plastics

With its Closed Loop system designed specifically for the ceramic industry, Aliplast retrieves, recycles and converts the plastic films used to wrap pallets, giving them a new lease of life.

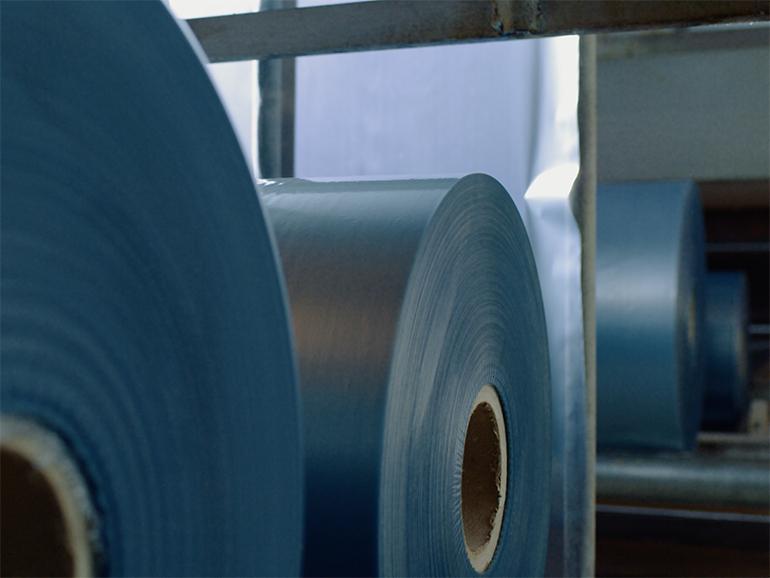

Rethinking plastic by transforming it from waste into a resource, from a problem to be managed into a solution worth investing in, has been Aliplast’s mission for more than forty years. What began as a pioneering venture has grown into Italy’s leading business for collecting and recycling post-consumer industrial plastics for the production of certified regenerated polymers, rLDPE flexible films and rPET sheets.

Based in Ospedaletto di Istrana (Treviso), Aliplast has been a member of the HERAmbiente Group since 2017 and now operates in Italy, Poland, France and Spain, handling every stage of the plastic packaging life cycle, from collection and recycling through to the production of new materials.

One of the company’s key activities is its collaboration with the ceramic industry through the Closed Loop system. The process begins at ceramic facilities, where plastic films used for the temporary wrapping of tile pallets – stored prevalently in outdoor areas – are collected and sent to Aliplast plants for recycling. There they are processed to create new raw material for the production of PELD Reload films, Aliplast’s top-quality range containing more than 85% recycled content. The cycle is completed with the return of the regenerated film to the ceramic manufacturer.

In Italy this operation is centred around Aliplast’s site in Formigine in the heart of the Sassuolo ceramic district, where around 600 tonnes of film is recovered and recycled every month. The successful model has been replicated in Spain’s Castellón cluster, where Aliplast Iberia has been operating since 2003 in Onda.

“Aliplast Iberia is already well established in the Spanish market, having grown by 45% last year compared with 2023,” explains Spanish branch manager José Nostrort Ramos. “We already work with several leading names in the ceramic sector here, but we aim to expand, building on the experience gained in the Sassuolo district, where we are the market leader.”

Aliplast Iberia is an efficient operational base with a warehouse both for products ready for sale and for storing film collected from clients, who are provided with constant high-quality technical and commercial support. New material production is the only operation that takes place in Aliplast’s Italian plants.

“Half of our Spanish projects follow the Closed Loop model designed specifically for the ceramic industry,” continues Nostrort. “Once used, the film is retrieved, regenerated and reintroduced into production, maximising efficiency and cutting waste. This is an advantage not only for the environment, but also for client companies, who can benefit from sustainable and responsible material management, as well as reducing their costs. For example, Spain’s recently introduced Plastic Tax adds a cost of €0.45 for every kilogram of non-recycled plastic. In Castellón, heat-shrink film is widely used for temporary pallet wrapping and is ideal for recovery and recycling because it undergoes short, repeated cycles. Switching to recyclable solutions can save up to €360 per tonne of film containing 80% recycled material, as in the case of recycled PE film which has a carbon footprint three times lower than virgin plastic.”

Aliplast’s latest products for the Spanish ceramic market include a pre-cut hood and a thermoplastic cover, both designed for packaging in intermediate stages of tile processing and supplied exclusively in reels for reduced thickness. These high-quality materials are capable of withstanding the elements (an important quality given that pallets are often stored outdoors) and meet the needs of small- and medium-sized ceramic manufacturers by combining functionality with sustainability.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks