“The secret ingredient”, ASCER’s new campaign to promote European ceramics

Launched simultaneously in key European markets, the campaign highlights the characteristics, values and qualities that make European ceramics truly unique.

What is the defining principle behind all the characteristics, values and qualities that make European ceramics unique? According to the Spanish ceramic tile manufacturers’ association ASCER, this hidden component is respect. A new promotional campaign by ASCER, financed by the Generalitat Valenciana and launched simultaneously in Germany, France, Italy, the UK and Spain, explores the way this secret ingredient is embraced by the European ceramic industry: respect for the environment; respect for the health, safety and rights of workers; respect for customers through meticulous attention to service; respect for ideas, which are transformed into innovation thanks to continuous investment; and respect for tradition and cultural heritage in a region renowned as the cradle of the ceramic industry and a global benchmark for quality, design, technology and sustainability.

The campaign includes a main video that uses emotional storytelling to highlight the traditions, customs, history and social and environmental commitment of European ceramics and illustrate how they are present in every moment of our lives.

In addition to the main video, the campaign also features four thematic videos that explore the defining characteristics of the Spanish and European ceramic industry. Industry professionals from the Spanish sector discuss specific aspects of ceramic production, sharing their knowledge and expertise and illustrating how each of these aspects embodies the “secret ingredient”:

All the campaign videos and materials are available in Italian, English, Spanish, French and German on the website thesecretingredient.info

Respect for the environment (video)

Ceramic is an inherently sustainable material, forged from earth, water and fire to create a natural, high-quality product. European manufacturers further enhance this sustainability by adhering to strict quality and environmental standards. They use advanced technologies to improve energy efficiency and minimise environmental impact and practise efficient resource management throughout the production process and in the reuse of materials. These are some of the measures already widely adopted:

- The replacement of energy carriers with lower-emission alternatives, where technically feasible: using electricity from renewable sources, adopting electric vehicles, implementing high-efficiency cogeneration systems, utilising natural gas in kilns, etc.

- Life Cycle Assessment (LCA) to optimise processes and guide companies in reducing environmental impacts throughout the product life cycle.

- Voluntary ecological quality labels (such as EPDs), which provide accurate information on the environmental impact of a product over its entire life cycle.

- Recovery of waste heat from kilns for use in other process steps, use of increasingly efficient burners and kilns, and high-efficiency cogeneration systems saving 20% primary energy.

- Recycling and reuse of 100% of wastewater.

- Recovery and reuse of 100% of the unfired clay waste and a large portion of the fired waste.

- Complete control of dust emissions during storage and transport of raw materials.

- Drastic reduction in the quantity of materials used in the decoration phase thanks to the adoption of digital printing.

With a growing number of ISO 17889-1 certified companies, the European ceramic industry has long been implementing energy efficiency measures and adopting best available technologies to reduce CO₂ emissions. This decades-long effort fits in with the goal of achieving net-zero greenhouse gas emissions by 2050. For instance, the Spanish ceramic industry has successfully reduced its CO₂ emissions per tonne of fired product by 61% since 1980.

Respect for customers (video)

Understanding, anticipating and meeting customers’ needs plays an essential part in the European ceramic industry’s ability to build lasting relationships with its partners. The key differentiator is the high quality of services provided, including personalised assistance, specialised technical support, consultancy during design and product selection, promotional tools for retailers, and showroom staff training on products, sales techniques, market trends and the use of support resources.

A commitment to innovation (video)

The European ceramic industry is the world leader in technological development, design and quality. This leadership is driven by continuous investment in research, development and innovation, coupled with the ability to anticipate and adapt to evolving consumer trends. With one-third of its production exported outside Europe, the industry boasts a strong global presence. Its competitiveness is further strengthened by synergies within ceramic clusters, where collaboration across the supply chain promotes the exchange of skills and expertise, keeping the industry at the cutting edge of technological developments and design trends.

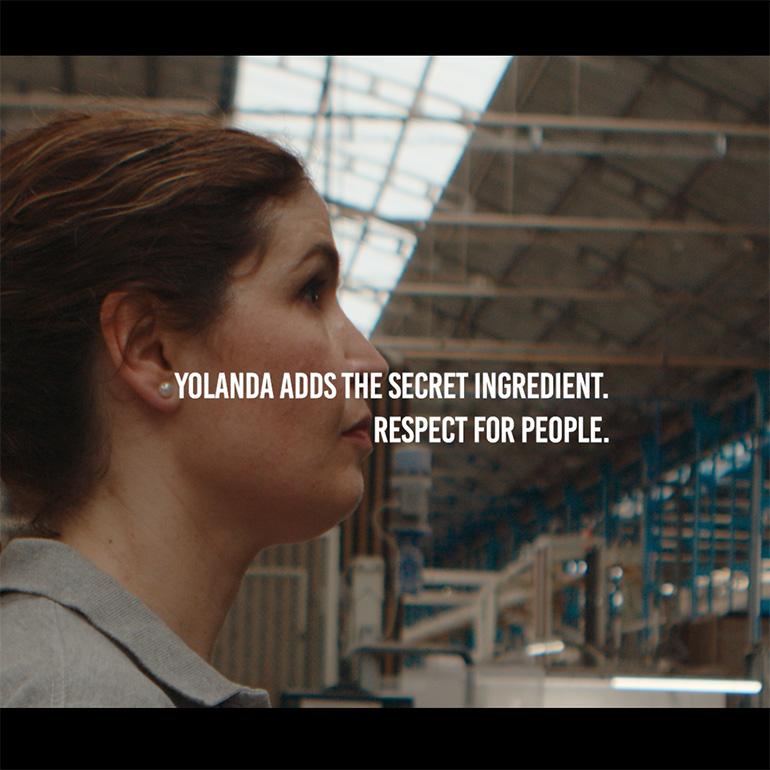

Respect for people (video)

The European ceramic tile industry currently employs over 53,000 people, including 15,000 in Spain, and generates an estimated three to four indirect jobs for every direct position. The sector adheres to stringent EU labour regulations, ensuring fair working conditions, health and safety, gender equality, non-discrimination, trade union rights and essential contractual protections. EU safety regulations are particularly rigorous, mandating the use of personal protective equipment (PPE) and the installation of physical protection devices on machinery.

Ongoing innovation in production processes, with increasing automation and digitalisation, has significantly reduced manual tasks, allowing employees to focus primarily on control and supervision.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks