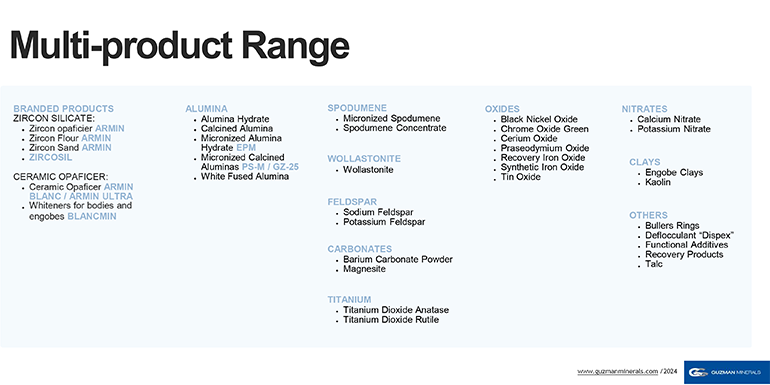

Guzman Minerals’ multi-product range

With 85 years of experience in the market, the Spanish company now focuses on further expanding its international presence and strengthening its brands such as ARMIN and ZIRCOSIL.

Founded in 1939, Guzman Minerals is a Spanish family-owned multinational company dedicated to meeting customers' diverse product needs with high levels of quality, availability and service. In 2024, the group celebrated its 85th anniversary, reaffirming its focus on the minerals sector while setting ambitious new goals. These include further expanding its international presence – which already spans more than 46 countries – and strengthening its brands such as ARMIN, specialising in zirconium silicate grinding, and ZIRCOSIL, tailored to specific market demands. With its emphasis on sustainable growth, Guzman Minerals continues to innovate and specialise in various industrial sectors while pursuing synergies to expand its product portfolio and provide optimised solutions and a high-quality service.

Guzman Minerals has also expanded its investments, both at its facility at Castellón (Nules) in Spain and internationally with the acquisition of a grinding facility in Malaysia. This new venture not only allows the company to establish a direct presence in Southeast Asia but also marks the introduction of a different type of milling technology. While the Nules plant employs a continuous dry process, the Malaysian facility utilises a batch-based wet system. This approach allows for the production of a wider variety of mixtures and finer grain sizes, further diversifying Guzman Minerals’ product range.

Guzman Minerals is committed to delivering top-quality zirconium silicate, an essential raw material for the production of high-quality, dense and durable ceramic products, thereby ensuring optimal performance in all industrial applications.

In the ceramic tile sector, zirconium silicate not only contributes to the exceptional whiteness of products through its opacifying power (a result of its high refractive index), but also improves properties such as hardness, wear resistance and chemical resistance. It is used for a wide range of applications in this field, from the production of frits, glazes and engobes to its inclusion in porcelain body formulations.

Zirconium silicate is also widely utilised in the production of glazes for sanitaryware and tableware. In the refractory industry, coarser grades of this raw material offer essential properties such as abrasion and corrosion resistance, a high melting point and very low thermal expansion.

Zirconium silicate is also used in precision casting, where it helps ensure precision and quality in the manufacture of complex components.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks