NATURALLY ARTIFICIAL

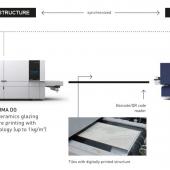

Durst Gamma DG tile glazing technology working for the Green Economy.

The result of more than 10 years of intense R&D efforts, Durst Gamma DG represents an unprecedented innovation that will set new standards in ceramic production and give a further boost to Italian manufacturing excellence. This solution produces tiles with an exceptional natural appearance and sense of depth, creating effects that are virtually indistinguishable from natural stone, marble or wood while maintaining all the advantages of ceramics. These natural and non-repetitive material effects are much in evidence in a number of new collections developed by Durst customers who are using this revolutionary technology in conjunction with Durst Gamma XD digital printers to create structures that synchronise perfectly with high-definition graphics.

The special proprietary Dimatix printheads used by Durst Gamma XD guarantee excellent quality, maximum uniformity across the entire width and total absence of banding even with material inks. This results in prints with vivid colours and sharp, highly contrasting details that enhance the three-dimensional effect of the Gamma DG structures. At the same time, the solution ensures high levels of efficiency even with non-stop 24/7 production, maximum reliability with low maintenance costs and zero downtime, thanks to the extremely long life cycle of the printheads (up to 10 million square metres printed without the need for replacement).

Durst’s innovative Gamma DG technology combined with the production excellence of the Gamma XD printer allows for the production of tiles that reproduce natural elements with an unprecedented level of realism and replicate the three-dimensionality present in nature. These innovative products are garnering prestigious accolades within the design world, as in the case of the Evoluta porcelain tile range produced by Ceramiche Piemme using a completely revolutionised industrial process featuring Gamma DG. Evoluta has been selected for the ADI Design Index 2021, which honours design products and services that display a high degree of innovation and focus on sustainability. This is exactly the case of the structures created with Gamma DG, which are made from non-polluting water-based materials.

More than ever before, awareness of the environment and the scarcity of raw materials are driving the growth of the green economy and leading to the development of sustainable projects that incorporate green technologies into traditional processes. Gamma DG technology also contributes to sustainable production processes by using water-based ceramic glazes.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks