A new clay for sanitaryware production

At Tecna 2024, Effediesse presented the technological test results of the SA01 clay for use in sanitaryware production, obtaining positive feedback from manufacturers visiting the fair.

Effediesse of Campogalliano (Modena) chose the international exhibition Tecna 2024 in Rimini this September to present its latest ceramic raw materials, one of which was the SA01 clay. While this material has already been successfully adopted in ceramic tile and slab production, the technological test results highlighting SA01’s potential for use in sanitaryware production drew particularly strong interest from visitors.

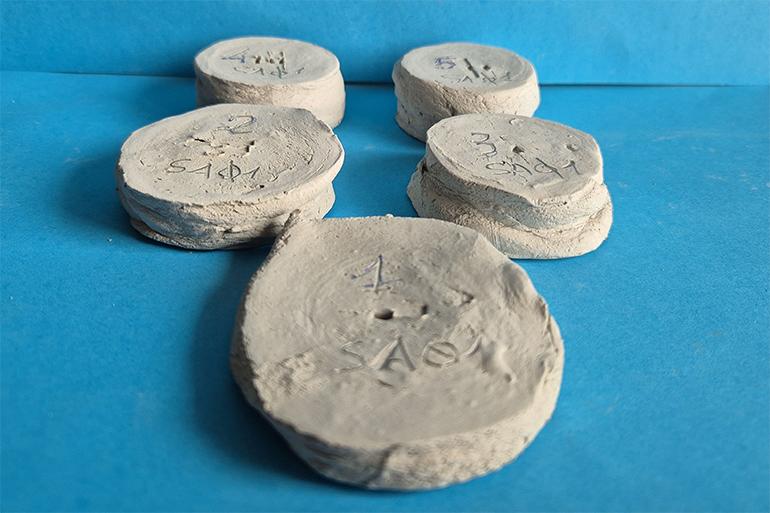

The laboratory tests aimed to evaluate the individual properties of the clay and its contribution to the overall characteristics of sanitaryware bodies when used in specific compositions.

The tests determined typical values for a number of characteristics of vitreous china sanitaryware mixes, including pyroplastic deformation, pre- and post-fire shrinkage, fluidisation, thickness formation and toughness. In particular, the plasticity of the individual material was found to contribute significantly to the overall plasticity of the final body. The material also offered an advantage in terms of post-firing colour, displaying a particularly high level of whiteness even as an individual component.

The residue found in dissolved preparations consisted primarily of siliceous material, which makes a positive contribution to milling processes and becomes a beneficial component of the composition.

Following the positive reception at Tecna, Effediesse has already received requests from several Asian manufacturers to develop bodies using SA01 clay with a view to improving body characteristics and lowering production costs.

Table 1 shows the main technical characteristics of the SA01 clay found in the tests.

|

Plasticity (Pfefferkorn) => Pfefferkorn number |

29.0 |

|

Mechanical strength of sample dried at 110°C in 24 hours |

34.07 Kg/cm2 |

|

Shrinkage after drying at 110°C |

6.25% |

|

Shrinkage after firing at 1240°C |

7.34% |

|

Total shrinkage at 1240°C |

13.59% |

|

LOI / Perdita al fuoco |

7.23% |

|

Water absorption at 1240°C |

0.22% |

|

Pyroplastic deformation of fired test specimen |

34 mm |

|

Colour after firing |

Light grey |

|

Colour after firing with colorimeter evaluation |

L= 77.85 a= 2.55 v= 9.99 |

Technical notes: deflocculation and particle size

In laboratory tests for deflocculation, the SA01 clay displayed limited reactivity to sodium silicate but a highly positive performance with polyacrylate and acceptable results with sodium tripolyphosphate. This means that when sodium silicate has a limited effect, suitable casting parameters for a body can be achieved using polyacrylate.

As for particle size, the residue on the DIN 20 sieve (300 µ) lies at the upper end of the range of standard values. This indicates that the clay is a sandy material that is particularly well-suited for preparation processes based on grinding as well as those based on dissolving.

The values of plasticity, mechanical strength, shrinkage, LOI, water absorption and pyroplastic deformation all fall within the average range for clays used in sanitaryware production.

The low water absorption value makes a positive contribution to sanitaryware body compositions by helping to achieve an appropriate total relative value.

The laboratory tests were backed up by a production test of a sanitaryware article carried out by a major Italian group, which confirmed the findings of both the material technical analysis and the body tests (Figures 3 and 4).

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks