“We ARE Tableware” by Sacmi will be protagonist at Ceramitec 2022

SACMI will be a key player at Ceramitec 2022 (Munich Trade Fair, 21-24 June) with its benchmark technologies for the Tableware industry, as well as for Powder Metal, Hard Metal, Refractories, Technical Ceramics, industrial kilns.

Under the motto “We ARE Tableware”, Sacmi will present the latest solutions developed by its network of companies, Sama, Riedhammer, Gaiotto, Sacmi Imola: an all-round proposal for tableware production that focuses on automation, sustainability and efficiency.

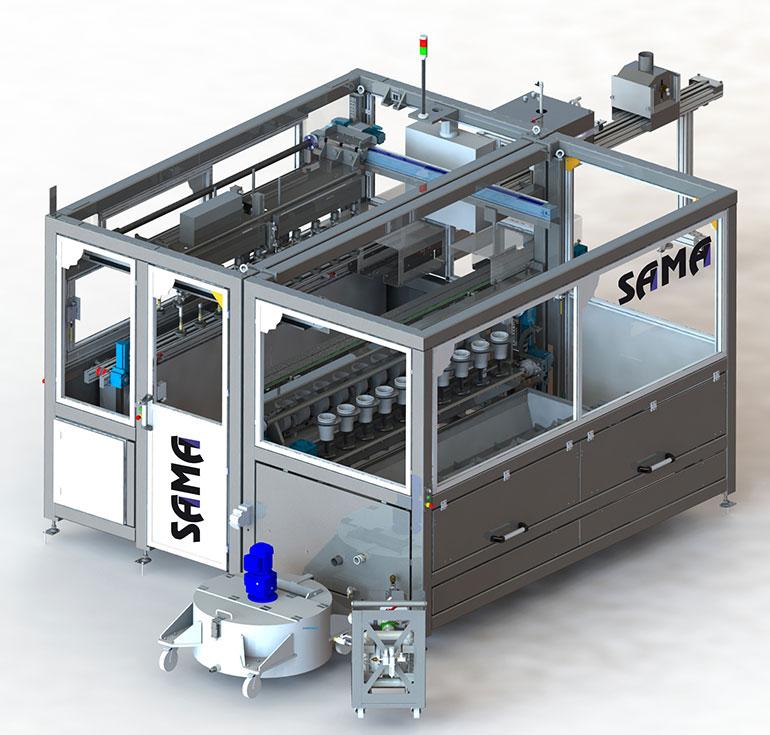

In the foreground at Ceramitec is the SAMA proposal, which has consolidated the PHO 700 Green isostatic pressing solution on the market. Preferred by the main players in the sector, the solution offers maximum versatility in the management of different production mixes, including “special” formats (up to 480 mm in diameter and 150 mm in height) which are increasingly in demand and appreciated by the market, such as oven-proof dishes, large mugs, etc. With PHO 700, demoulding of the heaviest, widest and deepest items can be facilitated with the optional demoulding device. The distinctive features of the solution and its uniqueness in the market make it possible to integrate downstream, even for the widest items, solutions for automatic and robotic finishing, developed in partnership with GAIOTTO.

Alongside this are the devices for reducing consumption by up to 30% that characterize SAMA's “Green Series”. The tableware proposal also includes DHD-D 908, a new concept digital decorating machine that extends Sacmi’s extensive know-how and experience in ceramic decoration to the tableware sector. For the firing of the products, Sacmi will show the industrial kilns developed by Riedhammer, which offers complete solutions for managing the firing of any product: biscuit ware, glazed or single firing, reduction kilns for porcelain, but also stoneware, terracotta, vitreous china, as well as for items requiring a special atmosphere, e.g. bone china.

Riedhammer now uses a modular approach to kiln design, which is configured and personalised in accordance with each customer’s requirements. For example, by developing fixed or modulated air combustion regulating systems, patented burners, sensors for measuring the oxygen content and the atmosphere inside the kiln. All new-generation kilns are equipped with advanced emission reduction and energy recovery-saving packages through both direct and indirect solutions. Research into new alternative fuels such as hydrogen from renewable sources is particularly advanced, with a range of kilns already equipped to accompany the evolution of the infrastructure.

Among the opportunities for Ceramitec visitors Sacmi will offer the possibility to visit the nearby Sama headquarters to see first-hand the pilot plant and Research Centre, state-of-the-art facilities where customers can carry out all product development tests prior to industrialisation.

Among the most recent initiatives carried on by Sacmi in the tableware sector, we mention the publication in 2021 of the first complete book on tableware technology, a unique initiative in the panorama of industry publications that Sacmi has offered free of charge to its customers to accompany the development of know-how and innovation, focusing on people training and the principle of partnership for the development of new ideas and projects.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks