Bongioanni Macchine: dies with polyamide coated pressure heads for energy saving

Lower energy consumption and extruded product optimisation are the advantages of Bongioanni Macchine dies equipped with a special self-lubricating polyamide coated HE pressure head.

A well designed die not only reduces clay consumption by optimising the size and weight of the clay bats but also eases the extrusion stresses that adversely affect the product drying process. It is worth remembering that in order to form a tension-free bat, it is also necessary to use a suitable pressure head (clay accumulator) prior to the die.

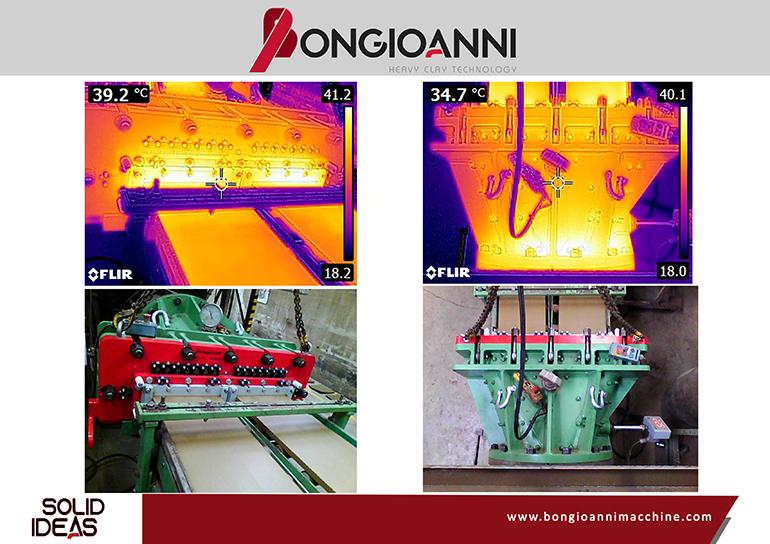

The special self-lubricating polyamide coated HE pressure head from Bongioanni Stampi, a division of Bongioanni Macchine, guarantees a more uniform clay flow than the traditional steel pressure head, thereby resulting in significant energy savings.

The flowability of the raw material over steel surfaces is adversely affected by friction (heat generation = energy loss). As the coefficient of friction of the polyamide coating covering the interior of the pressure head is significantly lower, much less heat will be generated (lower temperature = less energy loss).

Under the same extrusion conditions and using a suitable die, the use of the polyamide-coated pressure head guarantees a lower extrusion pressure. This in turn results in lower energy consumption and a more uniform clay flow at any point in the die.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks