Natural surfaces and digital effects: Sicer’s research (part 2)

Digital glues, grits, glass-ceramic coatings, and transparent matt digital glazes allow to obtain a wide range of surfaces, from matt-lapped marbles to anti-slip natural stones, from anti-reflective textured surfaces to absolute black.

In addition to the digital structuring agents, Sicer offers a range of materials to help customers create increasingly sophisticated, textured and three-dimensional products, including digital glues and grits, glass-ceramic coatings and transparent digital matt glazes.

Digital glues

Sicer’s range of digital glues now includes a wide selection of products, categorised by function into high-gloss glues (High-Glossy), universal glues and matt glues. These are all textural products containing a specific flux base and are either water-based or low-emission solvent-based (L.E. Low Emission series).

High-Glossy glues contain a flux specifically designed for use with high-gloss grits, ideal for both polished and matt lapped surfaces. These glues ensure excellent grit spread, high gloss and outstanding transparency.

Universal glues contain a multifunctional flux that can be used with both glossy and matt grits. They have a neutral transparent effect, making the grit-free edges of the graphic invisible, while again providing the vitreous surface with high levels of transparency and excellent grit spread.

Matt glues contain a flux in combination with technical matt grits that maintain their characteristics of fusibility. This allows for very natural stone effects, both at the kiln exit and when processed using new-generation lapping techniques.

Grits

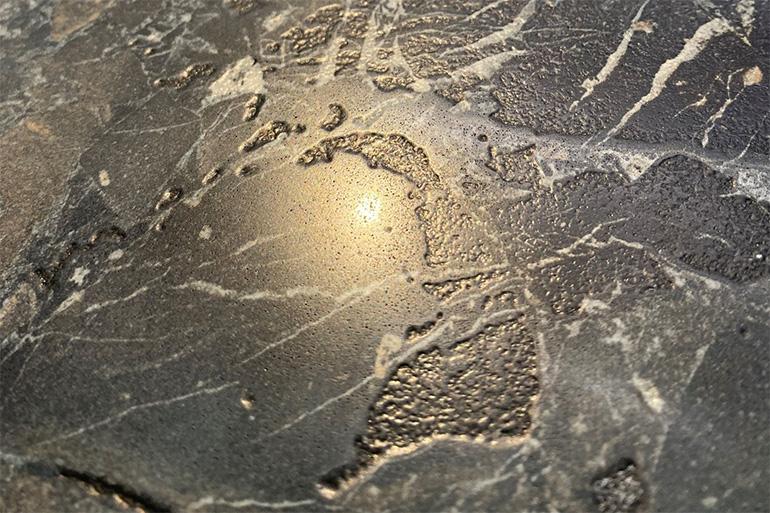

The use of digital glues allows for the precise deposition of grits, particularly matt grits, to create more natural-looking textured surfaces. A wide range of combinations is possible, even when using universal digital glue, which works well with both compact glossy grits and technical matt grits. These combinations allow for the creation of matt-lapped marble with negative veining and natural surfaces, even without additional processing.

Compact polished grits are now well known and consist of glass and glass-based mixtures that are carefully calibrated to ensure stable application in all dry deposition systems. Their function is to create highly compact polished surfaces with areas where microporosity levels are below 2%, while also regulating the firing behaviour of the glass. When combined with glitter-effect glass (ILLUMINA series) applied using digital glue graphics, it is possible to achieve natural surfaces with distinctive inclusions and crystalline veining in both neutral effect and coloured versions.

In response to evolving trends, new-generation stone-effect matt grits have been developed to create three-dimensional stone textures in combination with matt and universal digital glues. The use of specific grain size selections allows for high relief thicknesses as well as well-defined and compact edges. A major advantage of these products is their versatility, as they can be applied before or after engobing, as well as before or after drying.

Discharge volumes and application weights can also be adjusted, allowing the same product to be used to produce matt-lapped marbles with extensive surface grit coverage for negative veining effects, as well as natural stone-effect products at the kiln exit.

The matt grits specially developed by Sicer are divided into two categories according to the selected particle size:

- high-relief three-dimensional grits, which are designed to maximise final thickness and are therefore ideal for creating marble and stone effects with extensive surface coverage;

- detail-definition grits, which maximise edge definition and are therefore suitable for natural stone designs with high-definition detailing.

Both types offer a high degree of transparency and allow for stable application across all dry deposition systems.

Glass-ceramic coatings

Sicer has developed two surface solutions – Silky Rock Surface and Next Experience Surface – which create products with high technical performance that can be customised at a microscopic level. These surfaces can be combined with the application of matt grit or digital structuring agents to achieve products with high technical characteristics.

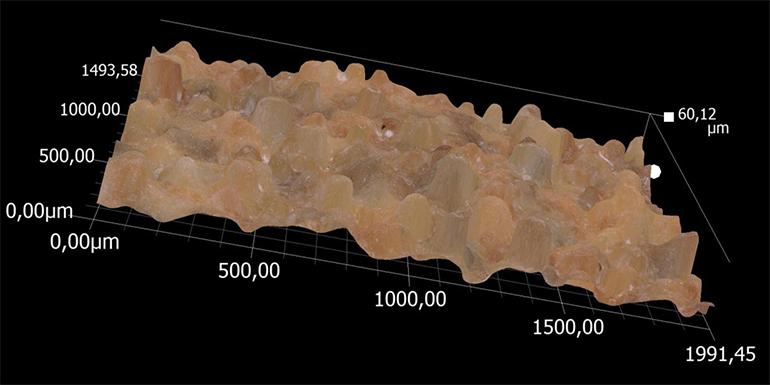

Silky Rock Surface is a modular finish that can be fully customised, for example in terms of anti-slip properties (ranging from R9 to R12). Even at higher anti-slip levels, it maintains an exceptionally smooth texture and exhibits excellent abrasion resistance (e.g. Mazaud test).

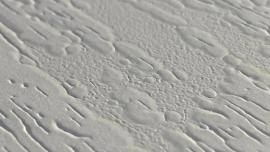

Next Experience Surface, the latest addition to Sicer’s portfolio, is a ready-to-use mix that is extremely easy to prepare and apply and offers a unique blend of aesthetics, functionality and performance. A special mix of nano-grits with an ultra-fine calibrated grain size, it creates fully matt, anti-reflective textured surfaces with enhanced cleanability and chemical resistance. The result is a technical vitrified natural surface, which is pleasant to the touch and non-slip (R9-R12), with gloss values between 1.0 and 4.0. It creates a fully transparent coating that is also suitable for ceramic collections in darker tones, including absolute black, thanks to a formula composed entirely of glassy grits.

Transparent matt digital glazes

Transparent matt digital glazes are designed to create surfaces that meet all current technical and aesthetic requirements, namely an extremely pleasant touch, anti-reflective properties (gloss units between 2 and 5), high chemical resistance, exceptional cleanability and extremely natural, crisp and vivid colours.

As with glues, digital glazes have been formulated in both low-emission solvent-based and water-based versions to ensure maximum sustainability. This is particularly important given that they are applied in large quantities: approximately 25 g/sqm for furnishing surfaces and 80-120 g/sqm for floor tiles.

From a chemical and physical perspective, these glazes have the same characteristics as standard digital products, meaning they are milled to a particle size of less than one micron to ensure high suspension stability and excellent filterability. Their surface tension and viscosity make them suitable for high-discharge printheads.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks