Ceramica Cielo purchases second Sacmi RobotClean finishing system

After being the first Italian sanitaryware manufacturer to invest in Sacmi RobotClean technology, Ceramica Cielo has now purchased a second finishing cell with automatic handling equipment.

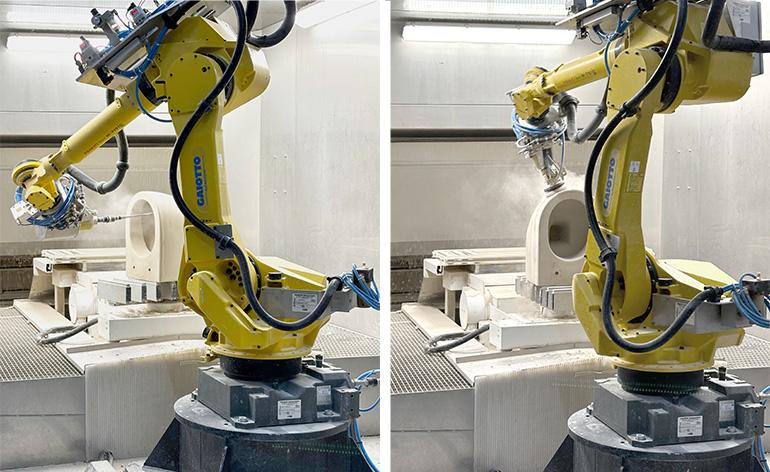

Sacmi RobotClean, an innovative solution for robotic sanitaryware finishing, brings numerous benefits such as eliminating manual handling and delivering consistent, superior quality finishes. Within a year of its launch, it has established itself as the go-to solution for the leading players in the Italian sanitaryware manufacturing district of Civita Castellana (Viterbo).

Ceramica Cielo was the first company to introduce this technology and following several months of successful operation has now invested in a second system.

This second complete finishing cell is identical to the first and was recently installed at Ceramica Cielo’s headquarters in Fabrica di Roma (Viterbo). The system incorporates a finishing robot and automatic handling equipment to transfer the piece to the cell for finishing and from there to the inspection station prior to glazing.

SACMI RobotClean eliminates the need for direct operator intervention on the piece. Once in the cell, a robot finishes the pieces using specialised abrasive tools in accordance with the instructions provided by Sacmi’s Smart Offline NG software, which is constantly updated and refined according to feedback from operators.

This complete white finishing ecosystem is the first of its kind on the market and marks a further step towards Sacmi’s goal of total production automation. It enhances the work environment and guarantees uniform finishing quality.

The second cell is also programmed to connect with the factory management system, allowing for precise tracking of all the operations performed on the piece, as well as data logging, instant generation of quality statistics and performance monitoring.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks