Duravit: Work continues at the Canadian plant

The new plant in Matane will be completed by September 2025 and will mark a milestone in ceramic sanitaryware production.

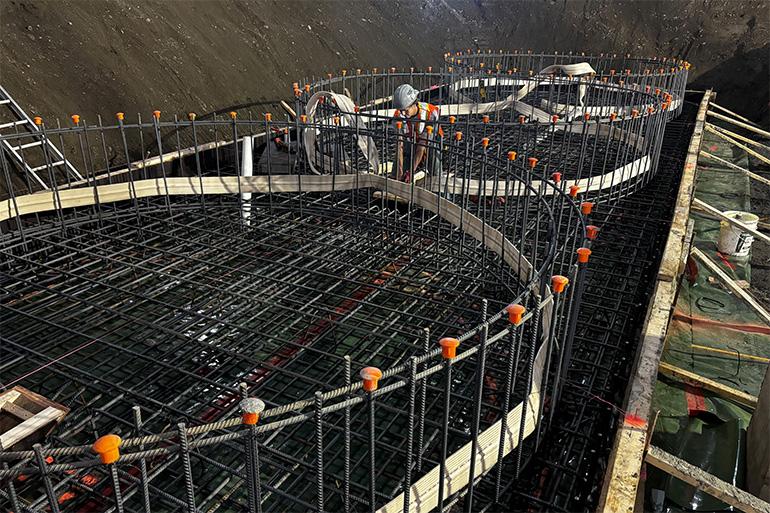

After the foundation stone was laid for the innovative Duravit ceramic sanitaryware plant in Matane, Canada, in July 2023, construction is now in full swing in preparation for its launch in 2025.

The plant is designed with a strong focus on environmental sustainability. It will feature the first electric roller kilns powered by nearly 100% renewable energy from hydropower, enabling an annual reduction of up to 10,000 tons of carbon dioxide through electric kilns and reduced transportation emissions. Furthermore, the new sanitaryware factory will stand out for its highly automated manufacturing processes and state-of-the-art technologies, ensuring superior quality and efficiency.

The 35,000-sqm production hall is almost complete and is now awaiting the installation of roller kilns specially developed for this facility. These kilns will allow the German multinational Duravit to manufacture ceramic sanitaryware in an entirely new way.

“We expect the first toilet to come out of the new electric kiln at the Canadian plant in the third quarter of 2025,” said Christian Gilles, Head of Manufacturing in Matane, who previously managed Duravit’s Bischwiller plant in France and the Hornberg facility in Germany.

The Matane site benefits from the combined experience and expertise of Duravit’s existing facilities.

“We’ve essentially assembled the perfect ceramic factory here,” explained Gilles. “The two roller kilns are undoubtedly the heart of the operation. The technology for the first electric roller kiln for sanitary ceramics was developed by Riedhammer, the world’s leading industrial kiln manufacturer, based in Nuremberg and a subsidiary of the multinational SACMI Group. The kilns run almost entirely on renewable hydroelectric power, allowing the Canadian facility to save up to 8,500 tons of CO₂ per year. However, since these machines are new to our production process, they present a learning curve.”

For this reason, Duravit is relying on well-established production methods and cutting-edge technological standards for the other manufacturing processes. The plant’s high level of automation ensures consistently high product quality, enhances productivity, and supports employees in their daily tasks. Additionally, Duravit is investing in driverless transport systems and a modern pressure casting process to further improve efficiency.

With its new manufacturing facility in Matane, Duravit continues its growth strategy. The new plant expands the company’s production capabilities alongside its existing manufacturing sites and headquarters in Hornberg, Germany. It also aligns perfectly with Duravit’s local-for-local strategy, which prioritizes sourcing materials locally and producing goods for the local market.

In this regard, the Matane facility, located directly on the Saint Lawrence River, optimizes logistics and transportation, reducing CO2 emissions by up to 1,500 tons per year. It will primarily produce sanitary ceramics tailored to the American market, reflected in a product portfolio specifically designed for this region.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks