GSI invests in Sacmi ALV

The Italian ceramic sanitaryware manufacturer is continuing the modernisation of its facility in Gallese (Viterbo) with the installation of a new ALV cell for high-pressure casting of washbasins and RobotClean technology for robotic finishing of sanitaryware.

Sacmi has recently completed the supply of a cutting-edge ALV cell to GSI Ceramica, a leading company in Italy’s high-end sanitaryware manufacturing district.

This latest-generation solution is dedicated to the production of modern countertop washbasins, high-quality, designer pieces that GSI will produce using the latest Sacmi RobotCasting automation technology.

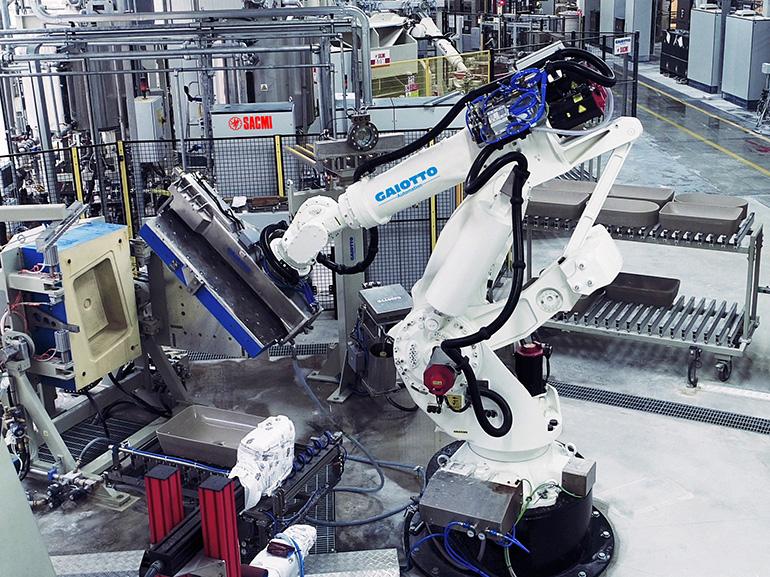

Designed to meet the growing demand for flexible, automated production, the ALV cell supplied to GSI consists of two casting modules, fully integrated with Gaiotto high-performance automation for demoulding, barcode printing and loading the finished pieces onto cars for further processing.

One of the cell’s key advantages is the flexible mould-handling system, which enables rotation of up to 90° to optimise casting and achieve high-quality, aesthetically flawless surfaces. As a result, pieces emerge from casting already perfect in every detail. A simple air knife removes residual moisture, allowing the piece to move directly to the next stage without any additional operations.

Another benefit of the ALV cell is the independent management of each work cycle, allowing the two modules to run in parallel and produce pieces with different shapes, sizes or even materials. Currently configured with two machines for a daily output of around 130 pieces, the cell is already designed for the addition of a third module, which would raise output to 200 pieces per day. This modular configuration allows production to be scaled up in line with future demand.

With this project, GSI further strengthens its partnership with Sacmi and continues its technological modernisation plan at the facility in Gallese (Viterbo), where Sacmi’s latest-generation robotised glazing solutions and RobotClean technology for robotised white finishing are already fully operational.

First introduced in 2020, RobotClean has quickly become a benchmark in the Italian market, offering repeatable quality, fully automated operation and enhanced workplace health and safety. Equipped with specially designed abrasive tools, RobotClean ensures efficient and flexible management of the various work stages (finishing of exterior and interior surfaces, rim, etc.). Dedicated filters facilitate dust abatement, keeping the robot’s working area clean at all times. Thanks to Sacmi’s Smart Offline NG programming software, the robot’s tasks can be programmed in a simple and intuitive manner, allowing operators to simulate the effects of the finishing operations on the real piece. The handling operations are also fully automatic.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks