Porcelanosa starts up new large-size slab factory

Porcelanosa Group’s Plant 4 came into operation at the beginning of the year and will produce 1.3 million sqm/year of sintered stone slabs to be sold under the XTONE brand name.

Spanish ceramic tile manufacturer Porcelanosa Group recently started up a new 36,000 square metre facility at its headquarters in Vila-real for a €55 million investment.

Plant 4 began operation earlier this year and will use state-of-the-art automation and technology to produce large-format porcelain and sintered stone surfaces under the Xtone brand name. The new facility has created 125 jobs and will have an annual output of 1.3 million square metres of 320x160 cm and 270x120 cm size slabs with thicknesses of 6, 12 and 20 mm. However, the installed production systems are capable of producing slabs in thicknesses of up to 30 mm and sizes of up to 360x160 cm, a special format that caters for the needs of the architecture segment.

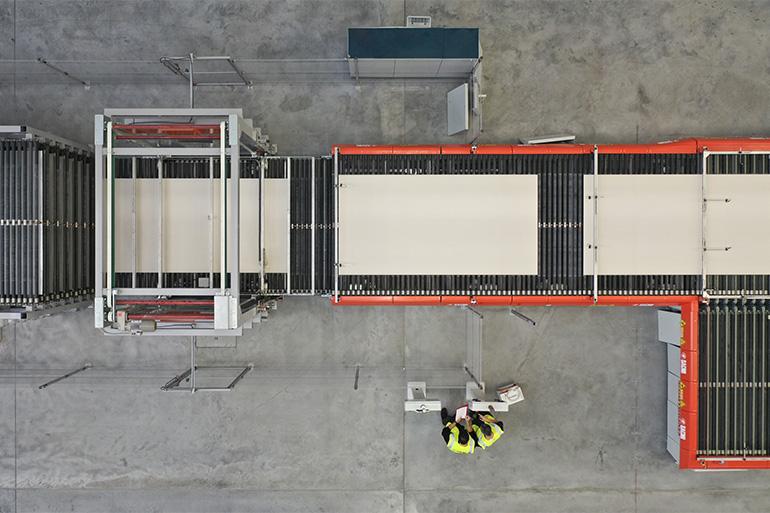

As a latest-generation smart factory, the plant stands out for the extremely high level of automation it achieves in all stages of the production process. Raw materials reception is automated using control software, while the pressing department uses the two most advanced presses on the market integrated with the latest 3D design technology. Glazing, decoration and texture creation are performed by a single system that achieves higher quality and resolution.

The firing department is equipped with a 250-metre-long kiln that produces products with the highest levels of technical performance ready for the subsequent cutting and finishing stages. A digitalised inspection system serves to sort and classify individual slabs and ensure that each piece comes up to the required quality standards.

For finishing operations, the post-production department has been equipped with a polishing line and a 100% automatic dry grinding line.

A highly sustainable factory

To increase energy self-consumption at the new plant, a total of 4475 solar panels with an output of 2.4 MWp have been installed on a 12,000 square metre photovoltaic roof, one third of the entire surface area of the new facility.

To minimise the environmental impact of the processes, the sustainability measures adopted at Plant 4 include recovery of 100% of the heat from the kiln for use in the dryer, reuse of 100% of the water via an industrial treatment plant and recycling of 100% of waste, which is fed back into the production cycle.

The international expansion of large-format XTONE slabs

The new production capacity available following the start-up of Plant 4 will enable Porcelanosa Group to significantly increase the sales of XTONE, the group company specialising in the sintered and natural stone slab segment. Last November, XTONE also announced the opening of twenty showrooms, referred to as Libraries, in Spain, Germany, the United States, Scotland, France, Italy and Brazil. The aim is to strengthen the company’s national and international presence by creating its own extensive distribution network, to give a further boost to its business and to consolidate the brand as a benchmark in the large-size slab sector.

Visitors to the Library centres will find a selection of sintered stone products in sizes 150x300 cm (thickness 6 mm) for floors, walls, furniture and façades and 160x320 cm (thickness 12 mm) for kitchen countertops. Natural stone surfaces with thicknesses of 20 and 30 mm are also on display.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks