Ceramic slabs: sustainability begins with raw materials

At Tecna 2024 Imerys presented its wide range of products for white and super-white bodies, as well as two solutions which reduce crystalline silica content in the slabs.

The ceramic tile market is driven by players who are constantly in search of premium products that stand out in terms of innovation. These offerings include large slabs for use on floors, bathroom and kitchen countertops, façades and furniture. Produced using advanced forming technologies, these continuous surfaces can be cut into the desired sizes, allowing for a revolutionary new approach to the world of design and architecture. The challenge is to enable the body formulations to adapt and develop in step with the new process technologies.

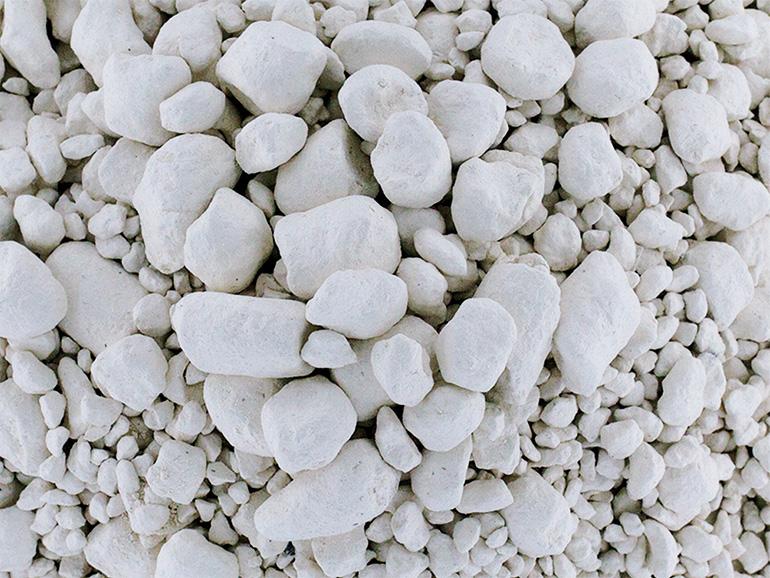

A wide range of products for white and super-white bodies

The use of raw materials with a low chromophore content allows for the production of bodies with a high level of whiteness, ensuring superior printing and decoration properties on tiles and slabs.

Imerys caters for the needs of the large tile and slab sector with a wide product portfolio that includes ball clay, white kaolin, feldspar and talc.

For example, the ball clay range includes FMT and premium FlashTop clay with a high degree of whiteness and plasticity originating from the Imerys quarries in France. They are used in proportions of up to 10% of formulations in combination with clays and kaolin to obtain white and super-white slabs.

With its wide range of kaolin-based products, Imerys is able to meet various specific requirements. For example, BIP kaolin mined in France is a high-quality product, renowned for its exceptionally high degree of whiteness, which also makes it ideal for the production of tableware. BIP also has high plasticity and good fusibility. CR kaolin, sourced from the Brazilian quarries and mainly used in tile production, has a high level of whiteness and opacity and a slightly lower plasticity. Kaoshine GL2, produced in the UK, stands out for its high plasticity and fusibility.

Imerys’ flagship feldspar is RF4, a sodium-potassium product from France. It has a high level of whiteness and a large sintering plateau, allowing for high temperature stability. It is widely used in the Italian ceramic industry due to its low shrinkage: formulations using 20% RF4 achieved 1% less shrinkage than other standard feldspars from Turkey, Germany, India and Sardinia.

As for talc, Luzenac 1445 from France increases the fusibility of formulations while achieving a wide sintering plateau, greater stability in firing and less deformation.

A new challenge ahead: respirable crystalline silica

Recently, there has been growing concern in the market about the crystalline silica present in ceramic slabs and engineered stone, an issue that manufacturers are taking seriously when choosing their formulations. For example, Western Australia has banned the production and supply of engineered stone slabs as of 1 July 2024, and further regulations on silica-containing products will be introduced across the country from September 2024.

To address this issue, Imerys has conducted research aimed at developing formulations that significantly reduce the Respirable Crystalline Silica (RCS) content in the slabs, from 15% (standard) to 8% or even less than 1%, without compromising the finished product’s performance characteristics such as water absorption, pyroplastic deformation, shrinkage and high modulus of rupture (Table 1).

Imerys has taken a two-pronged approach to reducing crystalline silica content.

The first is to use minerals with a naturally low crystalline silica content. For example, traditional albite and orthoclase feldspar, which contain between 8% and 12% quartz, have been replaced by a soon-to-be-launched feldspar from the Imerys deposit in the French Pyrenees. Similarly, traditional clays have also been replaced by clays with a high alumina content, such as Hymod Sigma, RR40 and highly processed kaolins such as CR and Kaopearl CNL30.

Secondly, Imerys recommends using minerals such as talc (Luzenac 2 or Luzenac 1445), which are capable of “digesting” fine crystalline silica particles.

As can be seen in Table 1, the absence of quartz grains in the finished product coupled with a higher alumina content brings advantages in terms of many mechanical properties. For example, bending strength increases by 20%.

| Standard formulation | Low crystalline silica formulations | ||

|---|---|---|---|

| Formula 1 | Formula 2 | ||

| Max. fired bulk density | 2,41 | 2,52 | 2,42 |

| Water absorption (%) | 0,1 | 0,14 | 0,1 |

| Shrinkage (%) | 7,64 | 9,66 | 8,93 |

| L* | 75,07 | 71,13 | 77,62 |

| a* | 1,3 | 2,9 | 0,15 |

| b* | 11,1 | 11,6 | 9,64 |

| Pyroplasticity index (cm-1) | 2,49E-05 | 2,35E-05 | 1,80E-05 |

| Bending strength (MPa) | 55-65 | 60-70 | 70-80 |

|

Crystalline silica content |

15 | 8 | <1 |

Imerys, a sustainability partner

Imerys’ technical teams are continuously in search of ways to develop solutions that meet manufacturers’ needs most effectively, including addressing sustainability-related challenges.

The strategic locations in Italy, Spain and Egypt enable Imerys to keep close to its customers in Europe, the Middle East and Africa, allowing for greater flexibility in the supply of materials and tailor-made solutions. Ownership of mines in Europe also ensures greater transparency of material supply routes and better overall management of the supply chain.

By 2025, Imerys aims to assess the majority of the products in its portfolio in terms of sustainability criteria, giving priority to those that contribute to 75% of its turnover. This further underscores the group’s commitment to sustainability, making it increasingly a partner of choice.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks