Franz Banke: from the product to tailor-made technology

Franz Banke, well-established partner in both the domestic and international markets, specialises in the production of clay roof tile moulds and other manufacturing equipment.

Founded in Isen, Germany in 1978, Franz Banke specialises in the production of clay roof tile moulds and other manufacturing equipment and is a well-established partner in both the domestic and international markets. Its comprehensive range of services begins with the design of clay roof tile models tailored to clients’ specific requirements and creative visions. These designs are brought to life using state-of-the-art 3D CAD technology, seamlessly connected to the company’s integrated manufacturing processes through CAM systems.

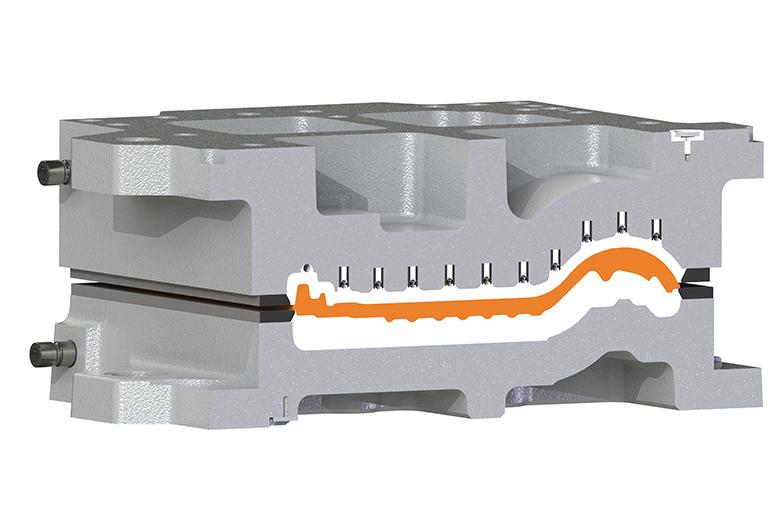

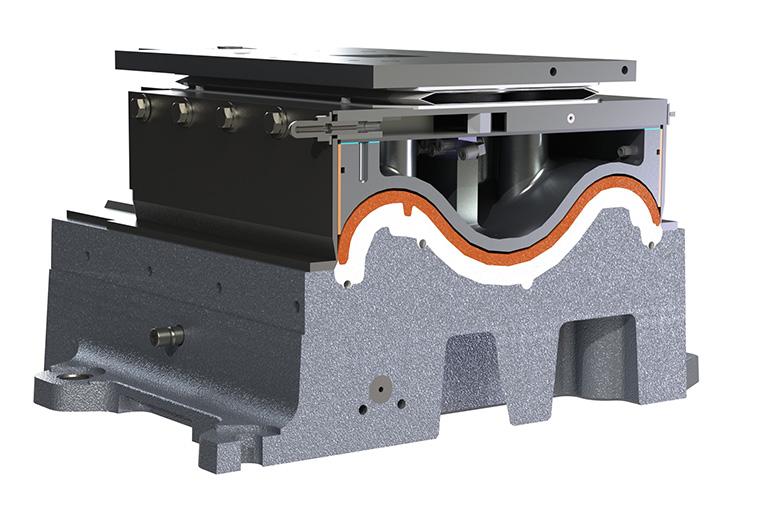

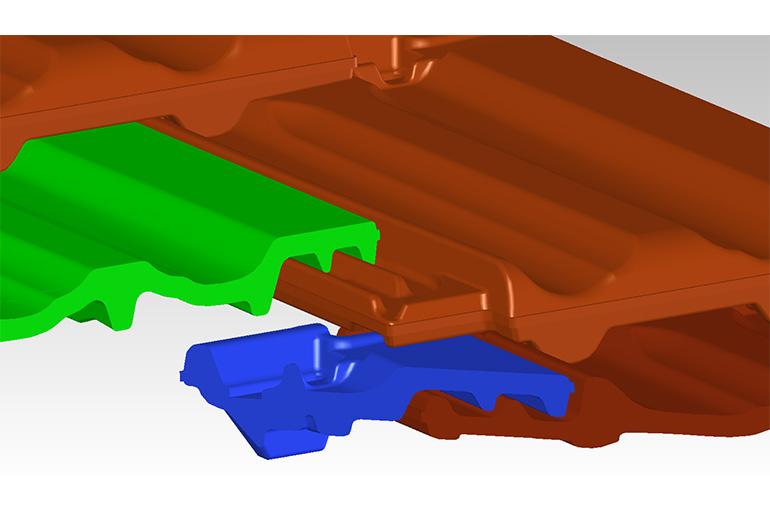

To illustrate a new tile model, the company can produce 3D prints to give an impression of the look and feel of a new tile. Based on the tile design and clients’ production requirements, working moulds, take-off heads and mother moulds are constructed and produced at Franz Banke’s integrated factory. The company offers all types of moulds, including moulds with gypsum inlays, moulds designed for rubber sheet applications (both plain sheets and preformed matrices) and steel moulds.

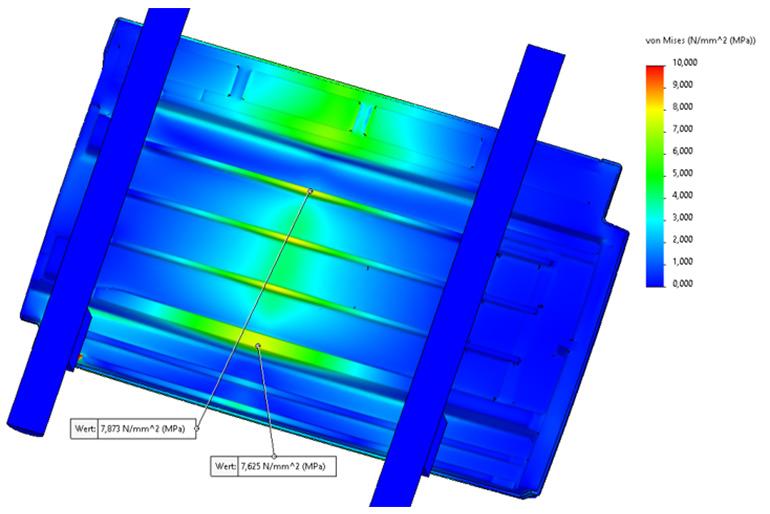

The Franz Banke team also excels in optimising existing tile designs using cutting-edge techniques such as the Finite Element Method (FEM) to reduce weight, cut costs and increase strength.

One of the company’s key strengths is its seamless integration of design, development, production and administration at its site just east of Munich, Germany. This concept, coupled with its skilled and experienced workforce, enables the company to deliver unparalleled flexibility, rapid responsiveness to customer demands, high quality and, importantly, competitive pricing.

Additional customer services include the provision of spare parts (e.g. border strips), repair of defective moulds or tools and replacement of outdated equipment.

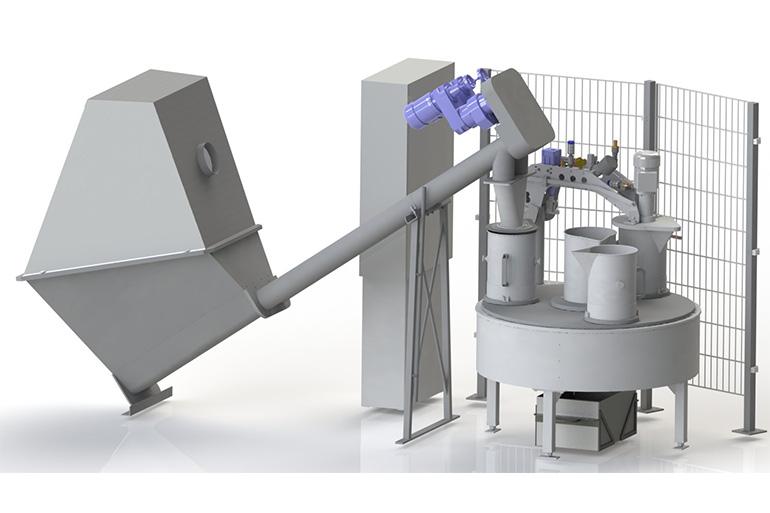

To offer a complete solution for production with gypsum moulds, Franz Banke also supplies equipment such as the AVM20, a completely automated plaster mixer with a capacity of up to 200 litres of gypsum suspension per hour.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks