The BMR Open Week is back

Special openings of the BMR Gallery in Scandiano, during the Cersaie 2023 week.

The product at the heart of the ceramic end of line processes. This is the theme of the next edition of the BMR Open Week from 26 September to 3 October. As per tradition, the company opens its doors to its customers to present its latest technological innovations, continuing a trend in which the most recent developments are centred around "Vision".

Thanks to the new Vision range, all types of BMR end of line systems are given a new life, completely redesigned from a digital point of view. The entire range has been reinvented thanks to new digital applications that increase the degree of autonomy and efficiency of the entire process.

Thanks to the extensive integration of machines and digitalization, the new range is able to offer a complete ecosystem that allows any type of requirement for tile and slab finishing to be handled flexibly and on a single platform. It also makes the production of small batches, just in time production runs and frequent format and surface changes more efficient.

Energy efficiency, environmental sustainability and supply chain optimisation are just some of the innovative features of the Vision system to provide an increasingly robust and sustainable process that is seamlessly linked to the theme of "industrial activity”, i.e., an approach to manufacturing that focuses on conserving energy resources and cutting costs by monitoring processes with digital cameras.

The first machine to undergo this process in this latest range designed by the Scandiano based company is the new Squadra Vision.

This advanced, fully automatic and engineered system is the first that has been derived directly from the traditional squaring machine with cameras, BMR’s cutting-edge technology. Continuous technological upgrades, integrated with Smart Factory and Industry 4.0 concepts, offer multiple advantages in terms of energy savings, eco-sustainability and production cost reduction. Tests, already carried out at the customers' facilities, show that with the same types of materials, removal rates and processing speed, this technology, which uses cameras, has a 40% lower grinding wheel wear compared to laser and similar technologies.

Another innovation that will be on display at the Gallery is the new Lap-digital-vision range, which focuses on aspects such as saving resources, both in terms of energy (lower consumption for the same production) and raw materials (using tools and abrasives more efficiently and using less water). All of this is made possible by implementing the new vision systems, the state of the art of what digitalization means today. Innovations in the new range include SuperShine, Digital Vision and Shine Vision.

SuperShine has evolved into SuperShine Digital Vision (a 12, 16 and 20 head range). The new version can manage one or more products independently thanks to the peristaltic pumps used for dosing the product, which have two supply channels. The ModBus communication system of the pumping circuit has been replaced by the more efficient EtherCat system, which ensures faster and more precise dosing, limiting the dispersion of the material. In addition, the temperature control feature allows us to improve the uniformity of the processing by avoiding problems related to sudden changes in temperature.

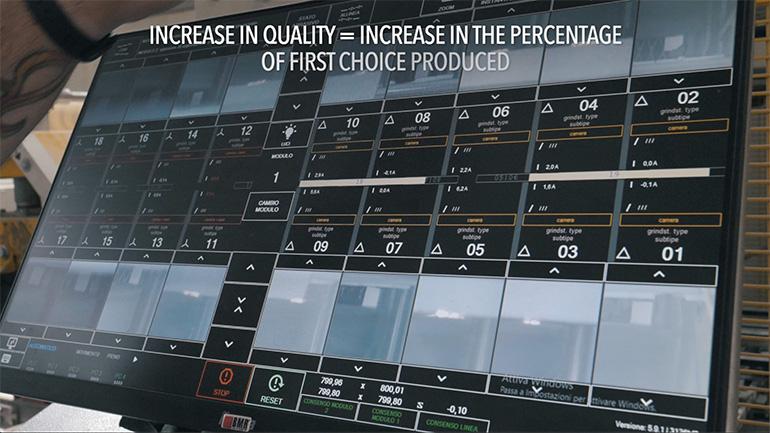

Another extraordinary innovation at the Open Week will be ShineVision, which is installed after SuperShine. This machine uses electronics and a vision system to check the surface of the finished piece after it has been processed. The machine can consist of a Gloss module (for Gloss mapping) and/or a Scratch module (which detects aesthetic defects and imperfections, reducing costs and increasing the percentage of first choice tiles).

The Lap-digital-vision range offers a number of real operational benefits, including:

- increased competitiveness, due to higher productivity;

- cost reduction, thanks to reduced energy consumption, less downtime and fewer rejects;

- automatic identification and correction of production issues in line, with machine vision that is part of the factory control system;

- improvement of sustainable working practices, thanks to the greater efficiency of the resources used, such as water and the wear of tools and abrasives and the reduction of defects;

- greater innovation, freeing personnel from manual and repetitive tasks for higher value work can lead to greater attention to detail in the process, facilitating problem solving.

The added value of this new BMR asset is the combination of the concepts of vision and industrial automation, which make it possible to recall the finishing parameters directly from the recipe and "correct" them in real time according to needs, maximizing synergies from a plant engineering point of view with the various tool and additive suppliers. With this solution, the operator becomes a process technician who, through a series of tools, is able to operate the line in the best possible way and correct the various production variables in real time.

The ability of BMR digital and industrial vision systems to process a large amount of information in a fraction of a second has positive knock-on effects for the entire production process, allowing products with negligible defects to be produced.

Other invaluable applications and services that can be explored during the BMR Open Week include:

- BMR iManager: the BMR digital platform which allows the customer to optimize production on the line and which enables BMR to activate a range of after-sales services to improve customer loyalty and optimise management. It is supplied with a standard Plug&Play system that is quick to install and can be customized upon request.

- Automation efficiency: optimization, development and testing of line automation. Communication standardization with external applications (MES, CRM, management ..)

- Production monitoring: displaying production data at various levels of detail

- Smart services: optimization of after-sales services (maintenance, spare parts, process)

The BMR team of experts will be on hand to discuss topics of interest with customers at the BMR facility for the entire duration of the event. You can already register by contacting your sales representative.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks