Electric kilns and dryers: towards decarbonisation of the ceramic process

Since 2023, Sacmi has developed a number of projects for electrically-heated thermal machines, such as gas-electric multichannel roller dryers, gas-electric vertical dryers, electric roller kilns and hybrid roller kilns.

By Pier Francesco Vaccari (Sacmi)

Since 2023, Sacmi has developed a number of projects for electrically-heated thermal machines. This report outlines the characteristics of gas-electric multichannel roller dryers, gas-electric vertical dryers, electric roller kilns and hybrid roller kilns.

Gas-electric multichannel roller dryers

The ECP and E7P dryers have one to seven roller decks and are equipped with electric heating elements alongside traditional gas generators. Although capable of fully electric operation, the presence of both heating systems means that the machines can be switched automatically to the most cost-effective energy source. This can be an advantage in the case of energy tariffs (especially in countries where electricity is cheaper) or if for example the ceramic producer has a surplus of self-generated electricity available at certain times of the day or periods of the year.

The electric generators consist of steel boxes housing a series of heating elements (coiled around ceramic tubes) that heat the air passing through them. The installed electrical power per Sacmi module (each 2.8 metres long) ranges from 80 to 300 kW, depending on the dryer’s width and number of decks.

This solution offers a number of advantages, including the option of partial electrification of the dryer thanks to its modular design. For example, in plants with heat recovery systems, hot air from the kiln’s cooling flue can be directed to modules operating at lower temperatures, while electrifying only those operating at higher temperatures. Here too, the machine automatically selects electric mode when it is more cost-effective, such as when self-produced electricity is available.

Another major advantage of this solution is that it can be quickly and easily retrofitted onto existing gas dryers.

One example is a project carried out in 2024 at a ceramic factory in Portugal, where Sacmi worked on a five-deck ECP dryer with a 2350 mm entrance width, 11.2 m length and a production capacity of around 5,500 kg/h of material with 6% incoming moisture content (equivalent to 300-320 litres/h needing to be removed). Each of the machine’s four modules was fitted with a 200 kW box, for a total installed power of 800 kW. In full electric mode, the machine’s energy consumption is 530 kW, which drops to 310 kW when kiln heat recovery is active. The dryer is connected to the facility’s rooftop photovoltaic installation and automatically operates in electric, gas or hybrid mode depending on energy availability. In the case of 990 hours/year of full electric operation (out of a total of 7,920 annual operating hours), CO2 emissions are reduced by around 100 tonnes/year.

Electric vertical dryers

The vertical EVA dryers have very similar technical characteristics to the horizontal models. Both gas and electric heating systems are used, allowing for automatic selection of the most advantageous energy source at any given time. Electric heating in these dryers is again provided by means of the boxes described above. The largest machines can accommodate four 375 kW units, providing a total installed capacity of 1,500 kW.

As with horizontal dryers, partial electrification is possible and can also be implemented on existing gas dryers.

Electric kilns

While electric kilns are not new to the ceramic industry, they are more complex than dryers in certain respects. However, they offer several key advantages over gas kilns, particularly lower specific energy consumption (about 15% less energy per kg of fired product) because electric kilns produce fewer flue gases and less heat is lost.

They also generate lower volumes of exhaust gases (around 70% less in full electric mode), reducing the size and energy consumption of the necessary filtering systems. Of course, a full electric kiln completely eliminates CO2 flue emissions from heat generation. Only a small amount (less than 10%) remains, caused by the oxidation of organic compounds released from bodies and glazes.

Electric kilns also offer a number of operational benefits. Particularly in systems operating purely through radiation, they ensure more precise temperature control and less wear on refractory walls and ceilings in the firing zone, thanks to the absence of mechanical abrasion by flue gases and flames.

As mentioned, however, electric kilns do face a number of critical issues.

One concerns gap management, which is slower than in highly responsive gas systems. In this case, it is advisable to install a storage buffer at the kiln entrance to avoid feed interruptions.

Another issue is the risk of chemical damage of the electric heating elements in the kiln preheating zone caused by substances released from the ceramic bodies and glazes. In the past, this problem made it necessary to build hybrid kilns that adopted gas preheating and used electrical power only for the maximum-temperature firing zone.

Yet another problem is the potentially very high total installed electrical power. For instance, a production of 10,000 sqm/day of 60x60 cm tiles with a 9 mm thickness would require about 6-7 MW of installed power, creating obvious infrastructural challenges if large numbers of factories in the Sassuolo area were to switch to electric power simultaneously.

Last but not least is the cost, as electric kilns require a higher initial investment than gas kilns of equivalent capacity.

Research at the Sacmi Forni laboratory

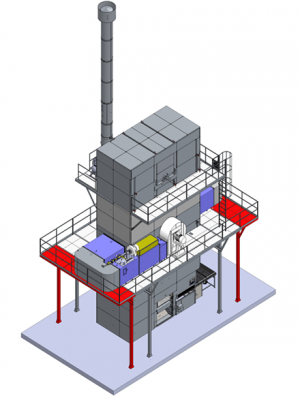

To address at least some of these challenges, Sacmi built a small electric kiln in 2024 at its Sacmi Forni laboratory and experimented with innovative technologies that have only recently entered the market. In particular, these include Flow Heaters, electric burners capable of heating air from ambient temperature to around 1100°C in a very small space. They are ideal for the preheating zone, where chemical attack is most severe. Because they are wall-mounted and traversed by a clean air flow, they never come into contact with substances released by bodies and glazes during preheating.

Solutions for the firing zone (from 1100°C to 1250°C) are already well established. These include radiant panels, used in narrow-entrance kilns for more uniform heat distribution, and traditional silicon carbide heating elements, which can also be used for wide-entrance kilns (3-3.5 metres).

Hybrid gas-electric kilns

As in the case of dryers, hybrid kiln designs are also a viable option. These systems use traditional gas burners for the preheating zone (up to 1100°C) and electric heating elements in the firing zone (up to 1250°C). While the benefit in terms of CO2 reduction is lower than in fully electric kilns, it can still amount to about 30%. In addition, the lower volume of flue gases allows for the use of smaller flue filters. As a result, hybrid kilns may serve as a practical first step towards full electrification of the ceramic firing process.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks