MDC (Machine Data Collector), smart supervision by SACMI-Gaiotto-IPREL

An IT architecture that keeps the key production parameters of casting, glazing and robotic finishing under control, all in real time. With immediate advantages thanks to proactive, instantaneous process management.

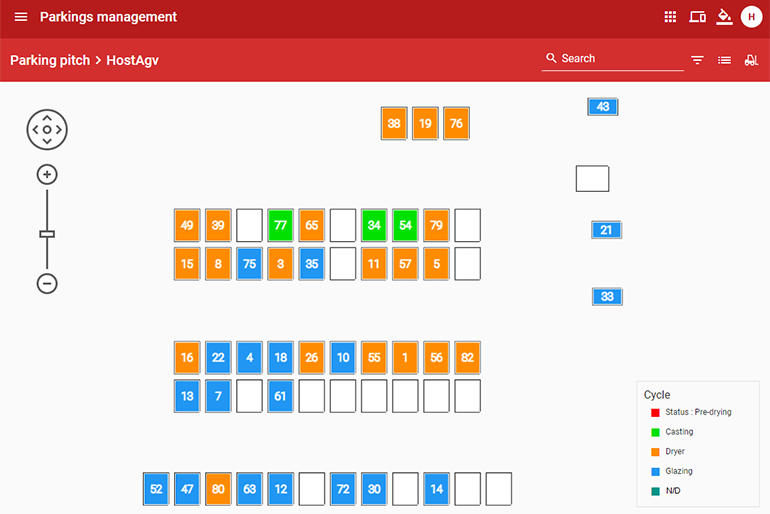

SACMI presents the MDC, or Machine Data Collector, a software package developed by SACMI together with Gaiotto and IPREL that gathers and manages machine production data, simply and immediately. This software is specifically designed for automated SACMI sanitaryware systems, from high pressure casting (RobotCasting) to robotic finishing and glazing (RobotClean and RobotGlaze).

In designing the MDC, Gaiotto and IPREL technicians focused on simplicity and user-friendliness, developing an IT architecture for individual cells and production departments that collects and processes all key data.

This includes, for example:

- productivity data by machine and by article family,

- machine-specific technical efficiency data

- the calculation of key performance indicators (KPI).

So what are the advantages?

Mainly: the elimination of paper documents; real-time process control; proactive management of alarms, maintenance and performance indicators.

A Gaiotto proprietary solution, the MDC streamlines access to the opportunities offered by supervision software, providing immediate benefits; it can be integrated on both simple and complex architectures.

Data collected and processed by the MDC can also be accessed remotely from any device connected to the company network.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks