Natural surfaces and digital effects: Sicer’s research (part 1)

Textured and three-dimensional surfaces. Find out how to obtain them using the wide range of Sicer’s digital structuring agents.

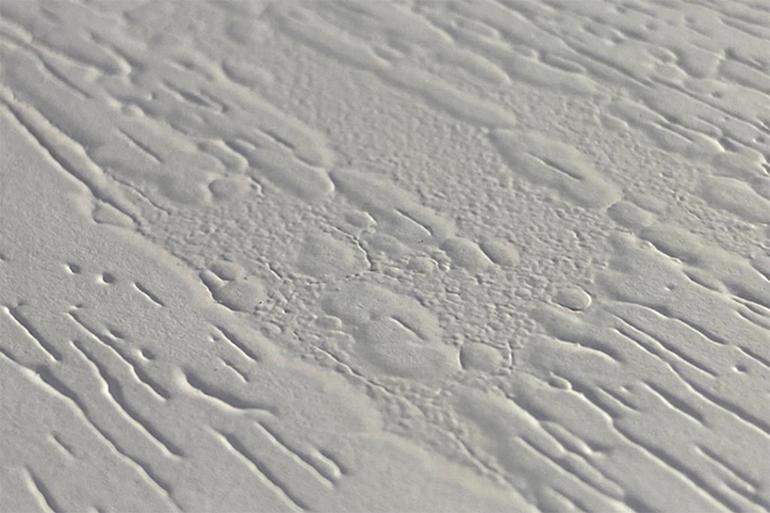

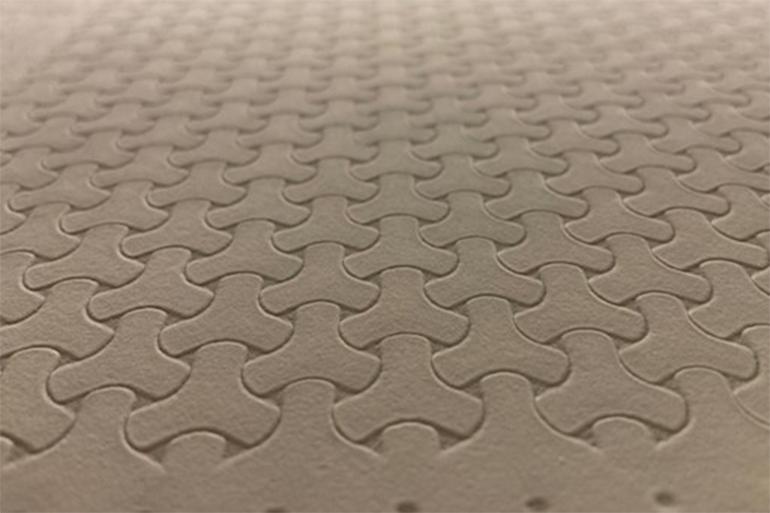

Sicer’s research focuses on developing ceramic and glass-ceramic materials capable of creating three-dimensional surfaces with outstanding technical and aesthetic qualities, as well as a wide range of digital effects, materials and colours that replicate the texture and beauty of natural materials. At the same time, digital products help improve the efficiency and flexibility of production lines, accommodating up to five or six product changes per day.

The growing use of digital applications on ceramic surfaces is evident in the layout of modern production lines, both in Italy and abroad. Increasingly, digital printers are being positioned immediately after the dryer to apply structuring or resisting agents, followed by an airless engobe application to create relief effects. Next, another digital printer is used to decorate the surface by applying colours, materials or special effects. The process is completed with a final digital application of glue and dry grit, followed by a final airless coating.

This layout can be modified, for example, by shifting certain digital applications to the pre-dryer stage. This makes it possible to deposit digital structuring agents (including water-based products), as well as digital glue and dry grit, to form an initial structured layer. When combined with the engobe applied after the dryer, this effect can be enhanced by adding a final digital glue and grit application at the end of the line.

Regarding the future prospects, the possibility of moving some of the numerous digital applications – especially more sustainable water-based ones – to the pre-dryer stage provides significant benefits. Applying digital materials while the ceramic body is still in the green state improves the performance and durability of digital products while extending the lifespan of application machinery. In this type of pre-dryer fully-digital line, a complete finished product can be obtained prior to drying through sequential application of digital engobe, colours and effects, followed by a final digital glaze. If additional technical characteristics are required, glass-ceramic coatings (Silky Rock Surface and Next Experience Surface) can be applied by airless spraying after drying.

Furthermore, incorporating a digital application of glue and grit alongside the engobe and colours at the pre-dryer stage can create a 3D line layout, resulting in a natural surface with superior technical and aesthetic properties.

Sicer offers a range of materials to help customers create increasingly sophisticated, textured and three-dimensional products, including digital structuring agents, digital glues and grits, glass-ceramic coatings and transparent digital matt glazes.

In this first article, let’s focus on digital structuring agents, their characteristics and how to use them.

Digital structuring agents

Sicer’s structuring agents now include a wide range of products, divided into:

- beginning-of-line structuring agents, which create deeper reliefs and are further classified into pre-dryer and post-dryer structuring agents;

- end-of-line structuring agents, which produce highly defined and pronounced reliefs.

Pre-dryer structuring agents, primarily used for slab production, can be either entirely organic or textural. The latter contain an inorganic component capable of hiding the colour of particularly dark ceramic bodies and have an innovative chemical composition that differs from that of conventional inks and materials. Additionally, they contain a cross-linking component that forms a water-repellent film during the drying process, ensuring the creation of the desired structure through the subsequent engobe application. These special structuring agents retain their resisting effect when dry, even several days after application.

Post-dryer structuring agents, suitable for both traditional tiles and slabs, have a chemical composition that is closer to that of standard inks and materials. They are available in opaque white and transparent matt versions, providing a strong textured effect with high relief and sharp, well-defined edges rather than rounded ones. The structure is created by exploiting the incompatibility between the solvent-based structuring agent and the aqueous phase of the engobe.

End-of-line structuring agents, the first in this category to have been developed, generate precise, well-defined structures while also ensuring accurate graphic alignment. Additionally, they can be loaded onto the last bar of the digital printer, eliminating the need to install an extra digital module. Sicer is also finalising the development of a water-based pre-dryer structuring agent, which offers several advantages over solvent-based alternatives. These include a reduction in volatile organic compound (VOC) emissions and odorous substances during drying, as well as compatibility with digital printers that operate in low temperature conditions and without issues related to vapour condensation.

To optimise the performance of structuring agents, the composition of the vitrified engobe must also be carefully developed. This requires precise formulation and accurate dosing of additives to refine not only the fundamental ceramic properties but also the rheological characteristics, ensuring the desired chemical and physical properties of the applied product.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks