Projecta: The evolution of digital printing

Innovation, research and a focus on electronics are the principles that have long been guiding Projecta in its efforts to develop new high-performance digital decoration technologies. This is clearly evident with the new PRO printer.

Innovation, research and a focus on electronics are the principles that have long been guiding Projecta (Gruppo B&T) in its efforts to develop new and increasingly high-performance digital printing decoration technologies.

This was clearly evident at Tecna 2022 in Rimini, Italy, where the go-to supplier to the Italian and international markets presented some of its latest flagship solutions.

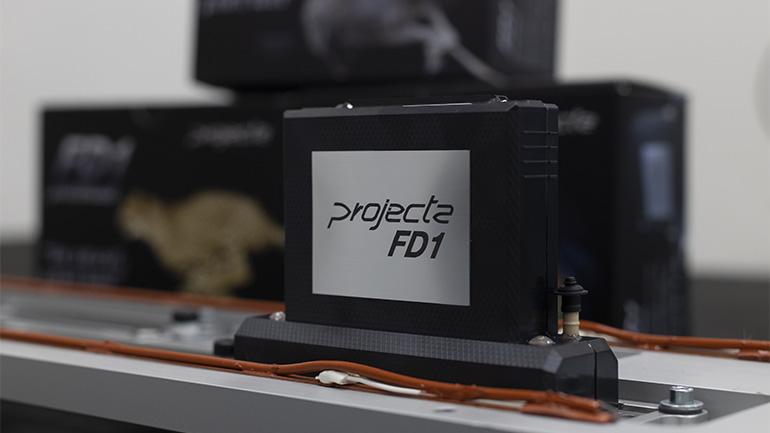

An example of this was the exclusive FD1 printheads. Designed to be the fastest printhead on the market while guaranteeing very high resolution, the FD1 are capable of printing up to 80 m/min. and stand out for their increased ink discharge and exceptional durability thanks to a stainless steel nozzle plate.

These outstanding characteristics are packed into a single instrument designed entirely by Projecta. Other highlights include the revamped IKON digital printer (723 mm print width) and the brand new PRO (1,360 mm print width) with 8 colour bars. This entirely new range of machines features a series of state-of-the-art technological solutions, including a new machine body, a new conveyor, improved cleaning and recirculation systems, new APOLLO electronics ready for future upgrades, new SPRINTA software and a highly intuitive user interface. This makes for outstanding ergonomics and ease of use combined with high levels of performance and quality.

The powerful new-generation APOLLO electronics include the RT2 - Real Time Squared feature, a print management system that allows any parameter to be changed in real time without the need to stop the line.

Also redesigned from scratch is the SPRINTA software which manages both automation and printing and has an even more user-friendly and highly customisable interface. SPRINTA is developed in accordance with Industry 4.0 criteria and can be integrated with the user company’s databases. It provides all production statistics and is equipped with automatic procedures for routine machine maintenance.

These high-performance new technologies are the result of Projecta’s unflagging R&D efforts, as the company prepares to launch its new 12-colour bar PLUS version printers onto the market by the end of the year.

Alongside its efforts to constantly raise the technological level of its products, Projecta is also committed to improving customer service with the aim of reaching out to a global market.

“Our goal is to consolidate our market presence and become the go-to global partner for digital printing technology, particularly in the ceramic industry,” comments Luca Fanara, CEO of Projecta. “Throughout this process, we are keen to convey our brand values and assure markets that choosing Projecta means having the guarantee of high-quality production based on our in-house expertise, as well as the certainty of a first-class, punctual and professional after-sales service and immediate spare parts availability worldwide.”

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks