Showcase of technological innovations by Durst at Tecna 2022

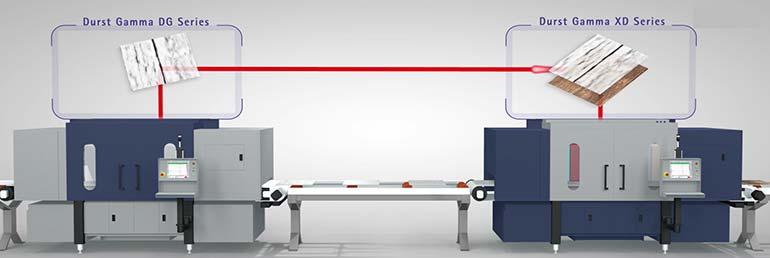

The Durst booth will be showcasing technologies for a full-digital glazing line featuring the Gamma DG system for digital glazing/structure printing alongside the Durst Gamma XD printer for decoration.

From 27 to 30 September, Durst will be back at Tecna 2022 in Rimini (Hall D1, booth 009) where it will be presenting the latest technological innovations developed for the digital decoration of ceramic tiles.

The Durst booth will be showcasing technologies for a full-digital glazing line featuring the revolutionary Gamma DG system for digital glazing/structure printing alongside the Durst Gamma XD printer for decoration.

This combination ensures that the structures are perfectly synchronised with the high-definition graphics, giving tiles a natural look and a sense of depth that is unmatched in products currently on the market. Visitors will be able to appreciate their uniqueness by visiting the gallery of applications made with these technologies at the Durst booth.

“Tecna has always been a benchmark for technologies dedicated to the ceramic industry,” says Norbert von Aufschnaiter, Segment Manager Ceramics at Durst Group. “This is why we are pleased to take part in the event to showcase the innovation of our Durst Gamma DG and Gamma XD systems, which represent the best answer to the new needs of the industry.”

The result of more than 10 years of intensive R&D work, Durst Gamma DG is to date the only technology that truly allows natural materials such as stone, marble and wood to be recreated on ceramic tiles.

This is achieved thanks to Durst’s proprietary RockJETTM printheads, specially designed to handle ceramic glazes with the large (up to 45µm), high-viscosity particles that are needed for printing high-definition structures to create visually striking and tactile effects.

This is done using water-based glazes with a very low organic content that minimise emissions during the firing process. In addition, the combination with Durst Gamma XD digital printers creates prints with vivid colours and sharp, strongly contrasting details that enhance the three-dimensional effect of the Gamma DG structures. The proprietary Dimatix printheads used on Durst Gamma XD guarantee excellent quality, maximum uniformity across the entire width and complete absence of banding.

This results in products with an extremely realistic natural look that are no longer distinguishable from natural products thanks to strong and high-definition material effects while maintaining all the advantages of ceramic tiles, including that of sustainability.

The use of Durst technologies makes it possible to reduce the use of natural raw materials in interior design applications while ensuring a truly green production process in terms of energy efficiency and reduced consumption, even in the case of non-stop 24/7 production. In addition, the ability to produce small and on-demand batches makes it possible to optimise resources, cut glaze waste and reduce the quantities of printed material held in stock and the related handling and storage costs

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks