Turning waste heat into clean energy

The French company Eco-Tech Ceram has developed and patented Eco-Stock®, a sustainable and cost-effective solution that supports the energy transition by reducing industry’s energy consumption and carbon footprint.

Today, more than a third of the energy consumed in industry is lost in the form of heat, which is equivalent to 2450 Mt of CO2 emitted each year worldwide. In the current geopolitical context of soaring fossil fuel prices and climate change, the recovery of waste heat is becoming an absolute priority. To meet this key environmental challenge, the French company Eco-Tech Ceram has developed an innovative, sustainable and cost-effective solution that supports the energy transition by reducing industry’s energy consumption and carbon footprint while improving its competitiveness. Called Eco-Stock®, it is a patented system that intelligently transforms waste heat into carbon-free energy.

Eco-Stock® for the decarbonisation of industry

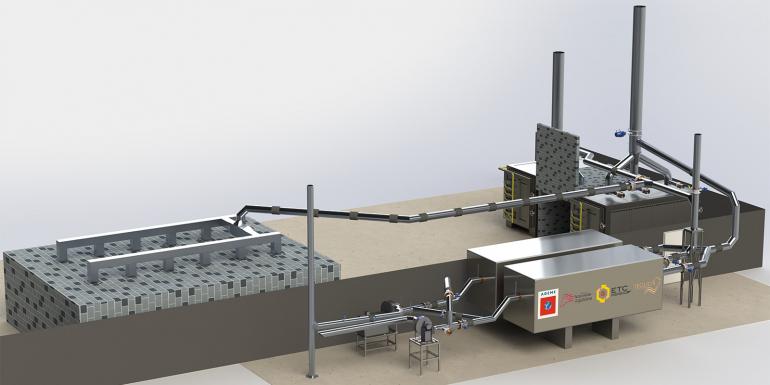

Eco-Stock® is a revolutionary high-temperature (up to 1,000°C) heat storage system that can be used to compensate for the intermittency and variability of deposits, sources and energy consumption. It consists of an eco-designed containerised rechargeable heat storage system capable of capturing, storing and releasing decarbonised energy more cost-effectively than by burning fossil fuels (natural gas, oil, etc.) while controlling the duration, power, temperature and speed of the energy flow. This innovative solution delivers energy with very high added value (high internal rate of return), enabling companies to grow sustainably and profitably.

Real, measurable and fundable benefits

Eco-Stock® is a mobile modular solution that can be adapted to any industrial site. It is suitable for a wide range of applications, including heat electrification and mass electricity storage. A multi-award-winning product (three times winner of the Concours Mondial de l’Innovation and winner of the ArcelorMittal Innovation Trophy), Eco-Stock® captures, stores and recovers high-temperature waste heat (higher than 300°C) from fumes generated by industrial furnaces in the ceramic, heavy clay, glass, chemical or metallurgical industries, redistributing it when and where required.

The real benefits are easy to quantify: up to 20% energy savings; a 10% increase in productivity; 1,000 tonnes of CO2 emissions avoided every year.

Eco-Tech Ceram’s multidisciplinary team of technicians and engineers provides customers with a turnkey technical and financial solution, a complete service ranging from technical and financial studies through to design, manufacturing, installation, monitoring and after-sales service. Moreover, the Eco-Stock® system can be adopted at zero cost, avoiding an investment payback time that was initially considered too long. To overcome this problem, Eco-Tech Ceram set up the company ETC Invest, which invests on behalf of the customer by purchasing the infrastructure from Eco-Tech Ceram then leasing the plant and/or selling decarbonised heat to the entire industrial system.

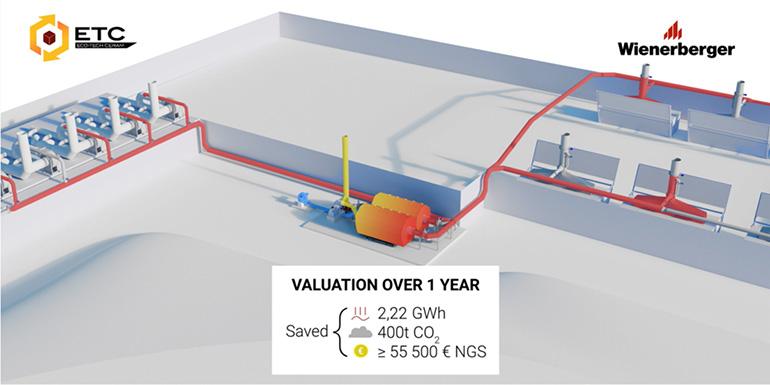

The collaboration with Wienerberger France

One of the first companies in the ceramic and brick industries to enter into a partnership with Eco-Tech Ceram was Wienerberger, which chose to install Eco-Stock® at its roof tile production plant in Pontigny, France. Here the system will be used to recover and store the waste heat generated by the six intermittent kilns. This heat will then be redirected to the intermittent dryers, which will no longer require gas to operate. This will reduce the plant’s CO2 emissions by more than 450 tonnes per year. The project fits in perfectly with Wienerberger’s environmental strategy, which involves reducing CO2 emissions by 15% by 2023, 40% by 2030, and reaching carbon neutrality by 2050.

“We are very proud to launch the Eco-Stock® project at our Pontigny site in collaboration with Eco-TechCeram,” said Frédéric Didier, Managing Director of Wienerberger France. “Installation of this innovative solution marks a further step towards the total decarbonisation of our facility, in line with our group’s ESG goals.”

“At a time when the climate and energy crises are intensifying, we are delighted to have been chosen by Wienerberger to accompany it in its transition towards net zero carbon,” said Antoine Meffre, chairman and founder of Eco-Tech Ceram. “Thanks to the solutions financed entirely by our company ETC Invest, the Pontigny site will benefit from clean energy without the need for any upfront investment.”

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks