Innovation for Efficient Recovery: Minerali Industriali Engineering’s REC Solutions

With the REC Solution series, Minerali Industriali Engineering (MIE) addresses the need for increased efficiency and sustainability. This comprises a range of highly versatile processes for recycling waste from various industrial sectors (ceramics, glass, stone conglomerate, industrial minerals), which are suitable for reuse within companies’ production cycles, ensuring a rapid return on investment and a significant reduction in disposal costs.

For recycling fired waste from the production of ceramic tiles and slabs, MIE has developed the REC Tiles range, enabling the recovery of materials currently destined for landfill and not yet recycled in current productions.

This system facilitates reuse through a process involving two key phases: grinding and particle size separation, through which the recovered materials are converted into new raw materials. Using Rec Tiles effectively reduces the environmental impact of waste and preserves valuable natural resources.

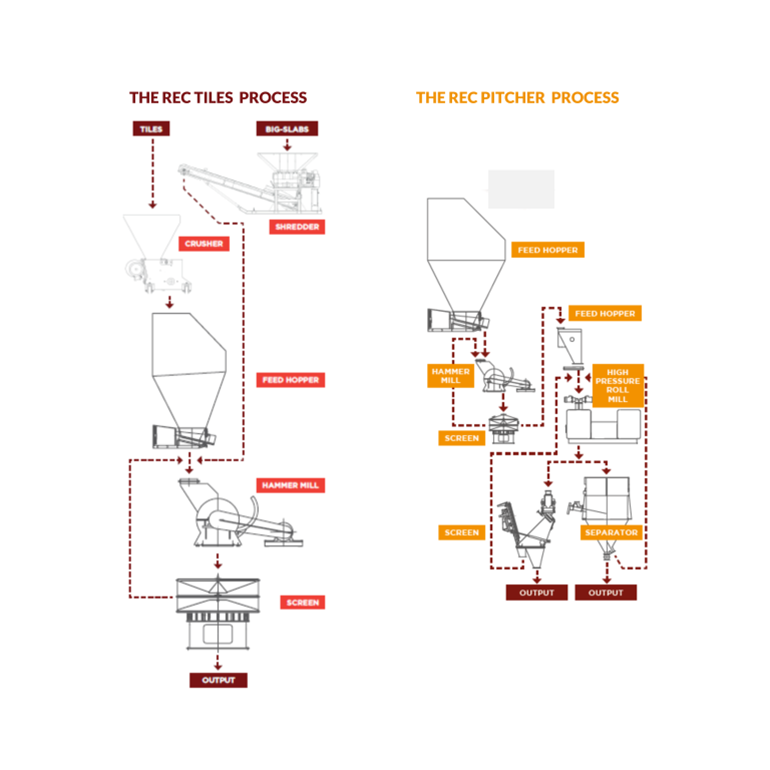

The Rec Tiles process begins with the pre-crushing phase, treating tiles and large slabs, followed by a second phase of coarse grinding of fired waste using a hammer mill. Subsequently, the resulting material is classified according to the specific requirements of the customer for various applications: the coarser portion, not reaching the desired dimensions, is rejected by the sieve and undergoes further treatment.

The plant can produce between 5 and 6 tons per hour, and the final product has a particle size of less than 5 mm. Storage of the finished product is customized to meet the specific needs of each product.

A similar solution applied to the recovery of fired waste from sanitary ceramics production is represented by Rec Pitcher. After an initial phase of coarse grinding in the hammer mill, the material is sieved.

Particles still too large are returned to the mill for another cycle, while the fine material is sent to the High Pressure Roll Mill where it undergoes a second grinding to achieve an even finer particle size. Again, the fraction exceeding the desired value is sent back to the high-pressure mill for regrinding. The particle size of the finished product can be either less than 250 μm or less than 75 μm (or any intermediate value), depending on the specific requirements of the customer. The plant has a production capacity ranging from 2 to 3 tons per hour, depending on production needs.

The REC solutions offered by MIE represent a significant step towards greater sustainability in the industrial sector, helping to reduce environmental impact and disposal costs, preserving valuable natural resources, and promoting a circular economy. With customizable production, these solutions prove not only sustainable but also economically advantageous for companies embracing innovation in industrial recovery.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks