Surfaces Group presents: Natural Finishing System

NFS - Natural Finishing System is the latest technology developed by Surfaces Group which combines satin finishing tools from Luna Abrasivi with Flexy Velvet fickert tools from Surfaces T.A. and can be complemented by a NoCoat protective finish treatment. NFS is the first solution capable of treating natural, non-lapped ceramic surfaces to create textures with an antique, timeworn look.

Surfaces Group is made up of a number of leading brands which work in close synergy in the field of finishing and chemical treatment of ceramic surfaces. Thanks to this collaboration, the group has developed a number of innovative technologies that set new standards in the market and enable it to act as a single partner for companies seeking customised solutions to optimise their production processes.

For this purpose, Surfaces Group has launched the World of Finishing project, which coordinates the group’s design and operational expertise and offers a range of specific finishing solutions for each type of ceramic surface. These innovative, multifaceted, exclusive and high-performance solutions are ideal for creating utterly new and original surfaces.

The NFS - Natural Finishing System technology

The latest technology, called NFS - Natural Finishing System, combines satin finishing tools from Luna Abrasivi with Flexy Velvet fickert tools from Surfaces T.A. and can be complemented by a NoCoat protective finish treatment.

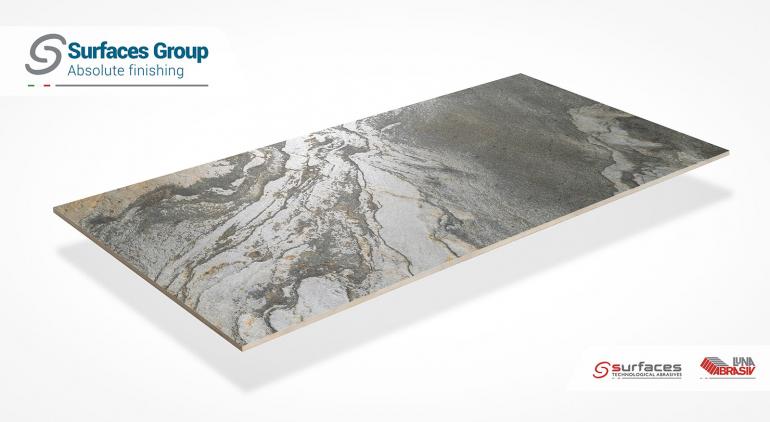

NFS is the first solution capable of treating natural, non-lapped ceramic surfaces to create textures with an antique, timeworn look. The combination of tools supplied by Surfaces Group creates a similar look to natural stone in terms of colour, pattern and surface texture, with a diversified effect both on the surface and within the structure of the tile itself. NFS is able to faithfully replicate the worn look of natural stone, such as the waxy appearance of Lecce limestone. The combination of tools results in a non-uniform look and feel, with each individual slab displaying waxy areas, irregularities and shade variations typical of ancient stone.

The dedicated software allows for diversified fickert tool set-ups for unlimited tile combinations in which the imperfections become a key aesthetic element, while the NoCoat treatment ensures that the surface is resistant to scratching, foot traffic, stains and mould.

The surface treatments not only protect the tile but also enhance its aesthetic qualities. NoCoat has expanded its field of expertise over the years, developing true multifunctional products that combine several properties in a single treatment. They functionalise surfaces by making them non-slip and water-repellent, as well as antibacterial and resistant to reactive agents.

In particular, the Gloss, Supergloss and ZeroGloss treatments have obtained the prestigious MOCA certification for food contact materials and objects. As well as protecting and sealing ceramic surfaces, these products guarantee the integrity of food and the materials they come into contact with such as kitchen countertops and tables (particularly important in the case of highly reactive foods such as tomatoes, citrus fruits, meat and fish). In addition to the formation of unsightly and permanent stains, surfaces treated with chemicals may release potentially toxic components into food. NoCoat certifies that the surfaces treated with its products remain unchanged and do not release any harmful components. This certification represents an important recognition of Surfaces Group’s ongoing research efforts aimed at ensuring increasingly functional and sustainable surfaces that protect people and the environment. NoCoat treatments are VOC-free as they do not contain formaldehyde, benzene or other volatile organic compounds that are harmful to humans and the planet.

NFS - Natural Finishing System, l’ultima tecnologia sviluppata, vede l’integrazione tra gli utensili satinatori di Luna Abrasivi e i fickert Flexy Velvet di Surfaces T.A. e può essere completata con il trattamento NoCoat per la finitura protettiva.

NFS permette per la prima volta di trattare la ceramica naturale, non lappata, per realizzare texture che la rendono vissuta, anticata. La combinazione di utensili fornita da Surfaces Group permette di creare un effetto simile alla pietra naturale, per colori, movimento e texture della superficie. I materiali sono mossi e creano un effetto diversificato su ogni piastrella e nella struttura stessa della piastrella. NFS riesce a replicare fedelmente l’usura della pietra naturale, ad esempio l’effetto cerato della pietra leccese. La combinazione degli utensili permette di ottenere trame disomogenee, non solo alla vista ma anche al tatto, ogni singola lastra presenta parti cerose, irregolarità, stonalizzazioni tipiche della pietra antica.

Attraverso il software specifico, Surfaces Group consente set up di fickert diversificati per ottenere infinite combinazioni di piastrelle sempre diverse, dove l’imperfezione diventa preziosa e viene tutelata grazie ai trattamenti protettivi di NoCoat che rendono la superficie sicura e resistente a graffi, calpestio, macchie, muffe.

I trattamenti superficiali, oltre a proteggere, esaltano la bellezza della piastrella. NoCoat in questi anni ha approfondito le sue competenze, elaborando veri e propri prodotti multitasking che riuniscono più proprietà in un unico trattamento: funzionalizzare le superfici rendendole antiscivolo, e idrorepellenti, ma anche più sicure perché antibatteriche o inalterabili a contatto con agenti reattivi.

Da segnalare, la prestigiosa conformità MOCA (relativa ai materiali e oggetti a contatto con alimenti) ottenuta per i suoi trattamenti Gloss, Supergloss, ZeroGloss. Oltre a proteggere e sigillare la superficie della ceramica, infatti, tali prodotti garantiscono l’inalterabilità dei materiali e degli alimenti che vengono a contatto con essi, come i piani cucina e i tavoli su cui appoggiamo alimenti reattivi (pomodori e agrumi, carne e pesce). Oltre agli inestetici e permanenti aloni che si formano, le superfici trattate con prodotti chimici potrebbero rilasciare agli alimenti componenti potenzialmente tossiche: NoCoat certifica che i piani trattati con i suoi prodotti rimangono inalterati e non rilasciano alcun componente nocivo. Questa attestazione è un importante riconoscimento alla continua ricerca per garantire superfici sempre più funzionali e sostenibili, per la tutela delle persone e dell’ambiente. I trattamenti NoCoat sono infatti VOC-free, perché privi di formaldeide, benzene ed altri composti organici volatili nocivi per l’uomo e per l’ambiente.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks