Digital innovation in natural ceramic textures

To enhance the three-dimensionality of ceramic surfaces without the use of an engraved punch or a dedicated roller, Sicer has developed several different types of texturing agents and digital glues.

Alan Nappa, Riccardo Mazzi - Sicer (Italy)

Digital innovation has always evolved in step with market trends, and this is particularly evident in the current market landscape dominated by demand for natural-looking ceramic textures. This has led to considerable research and development efforts aimed at fully exploiting the benefits of digital products in terms of cost optimisation and the potential for rapid and extensive customisation.

To add three-dimensionality to the ceramic surface without using an engraved punch or a dedicated roller, Sicer has developed various types of digital texturing agents suitable for different uses and desired final effects.

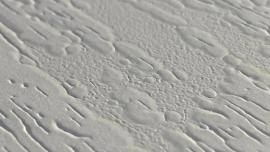

The texturing agent has a water repellency effect on the subsequently applied engobe and/or glaze and burns off in the kiln, leaving gaps on the tile surface. This results in a visible and tactile texture that can be further improved by combining the texturing agent with engobes and glazes with specific chemical/physical properties.

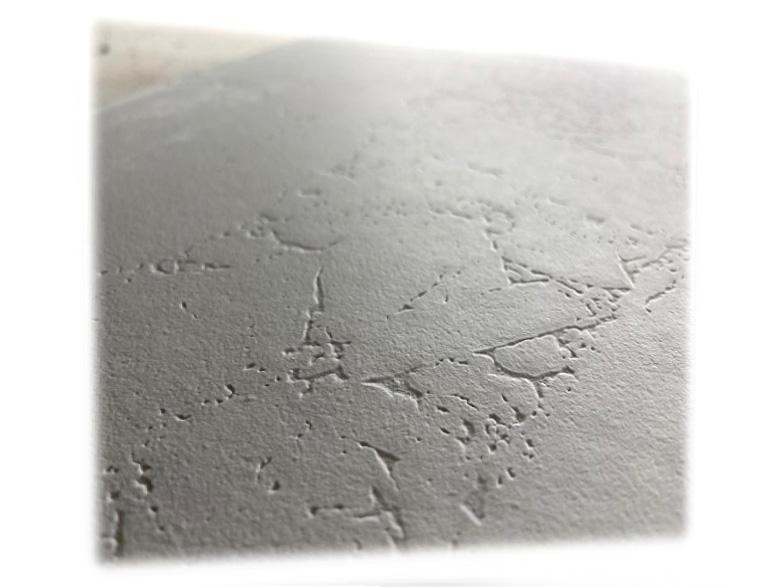

The first new product proposed by Sicer is a non-material-effect texturing agent with high repellency. Ideal for creating large surface gaps, this texturing agent has been specially developed for the production of large slabs and can be applied prior to the dryer, because even when dry its special formulation enables it to retain its water-repellency and resist effect. As a result, it is possible to apply engobe or glaze even after a period of several days.

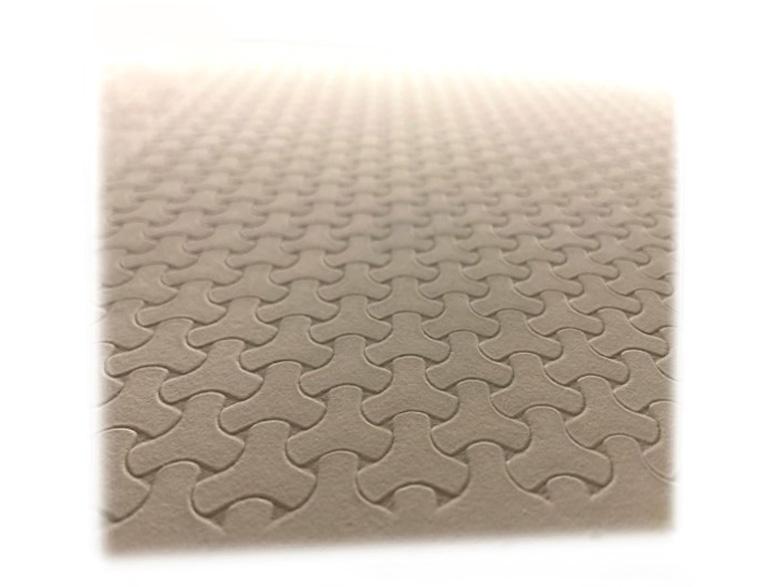

The Sicer range also includes an opaque material-effect texturing agent that is ideal for more traditional tile sizes but can also be used effectively on slabs. Its high level of detail and sharp edges make it ideal for reproducing natural stone with strongly defined incisions or wood with fine engravings. Unlike the previous texturing agent, the engobe or glaze must be applied while the product is still wet, i.e. just a few metres down the line from the point where the texturing agent is applied.

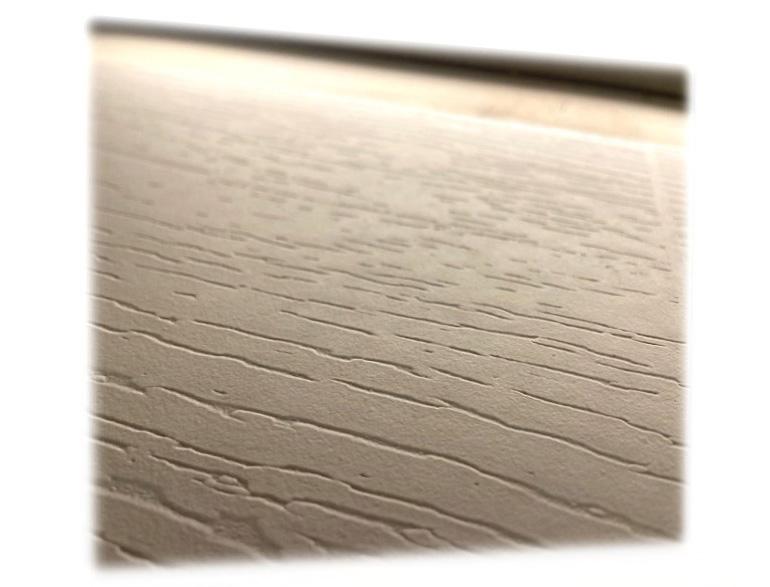

Finally, to cater for all requirements, Sicer has also developed a transparent matt material-effect texturing agent suitable for dark coloured designs or for the production of wood-effect tiles. It has the same characteristics as the previous texturing agent, and the two can be used in combination to create both transparent and opaque surfaces after firing.

To maximise the texturing effect of the digital product, it is important to perform an in-depth analysis of the engobes or glazes it is used in combination with to ensure they have the right rheological characteristics. It is also necessary to study the graphic design, which can enhance the visibility of the incision.

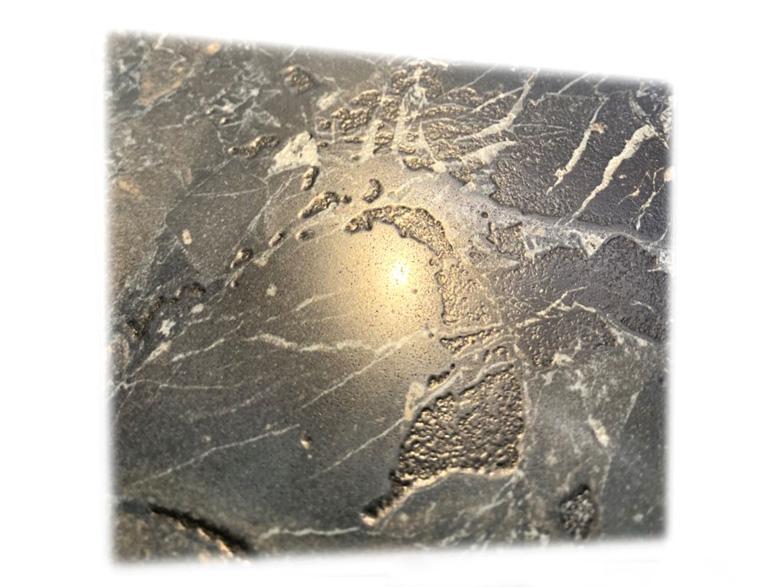

One additive technique that can be used to create a material-effect texture involves adding a digital glue + grit application to the resist effect of the texturing agent. This significantly increases the thickness of the texture and gives the ceramic surface a more natural look.

Sicer’s latest research has led to the development of two types of digital glue: a water-based glue with almost zero emissions approved for use with the printheads currently on the market; and a brand new low-emissions solvent-based matt glue which opens up a whole new range of aesthetic possibilities for natural surfaces.

This material-effect matt glue is designed to complement glossy solvent-based glues suitable for full-lapped and/or glossy grits and results in a neutral appearance after firing. It can also be used effectively in conjunction with grits designed to enhance the matt surface.

The key characteristics of this innovative product are its versatility and multifunctionality.

By studying a specific inorganic material-effect component, Sicer has developed a product that is capable of optimising technical/aesthetic results both with dry applications of matt grit and with applications of vitrified glossy grit.

Sicer’s new matt glue is the company’s flagship product for creating textured material-effect ceramic surfaces. It has developed a matt vitreous mixture and a compact glossy vitreous mixture (both with a dedicated particle size) which can be used in conjunction with a special surface finish to create three-dimensional vitreous decorations characterised by very low reflection and consequently very natural-looking edge areas.

By combining the two vitreous mixtures using the latest multiple grit deposition systems, a single line can rapidly (and simultaneously) produce a wide range of natural surfaces, thereby optimising costs and production time.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks